Potting of Ultasonic Parking Distance Sensors

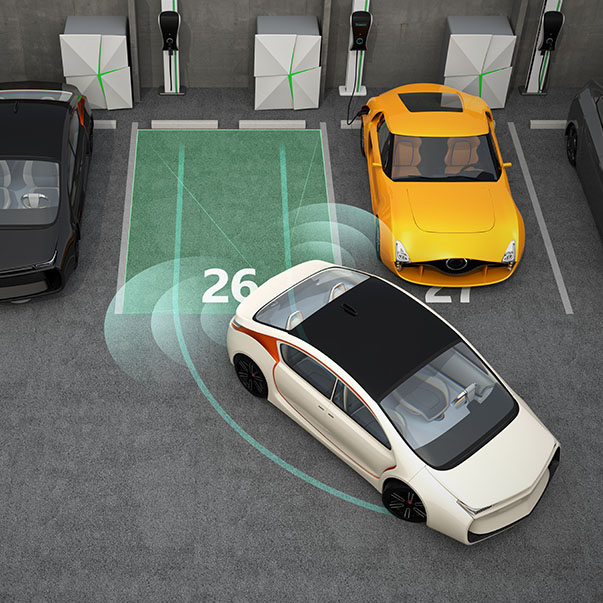

Advanced Driver Assistance Systems, commonly referred to as ADAS, are becoming far more common in modern-day vehicles. Key to enabling ADAS functionality is the cooperation of cameras, radar and LiDAR (Light Imaging, Detection and Ranging) as well as multiple ultrasonic sensor systems, all of which work together to identify objects, pedestrians and potential hazards for the driver, and thus ensure the safety of drivers, passengers and pedestrians. According to the measurement accuracy of the driver assistance systems used and the ultrasonic sensors, the recorded data is transmitted directly and immediately to the vehicle’s on-board computer. On the basis of this data, the connected control devices can trigger the necessary actions in real time.

Today’s vehicles have up to 8 distance sensors at the front and rear in the standard vehicle and 10 to 12 sensors in the premium vehicle. The sensors used today can calculate the distances even more accurately which is crucial for the safety of modern mobility and traffic systems, especially self-driving cars.

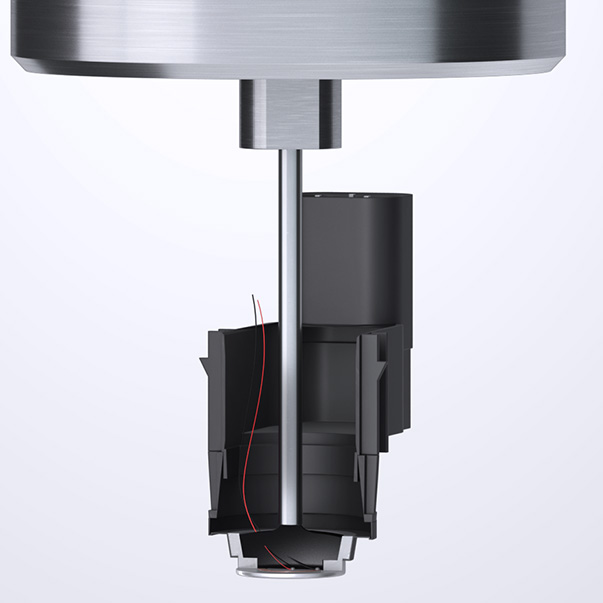

In order to ensure that your ultrasonic sensors can calculate distances with the highest degree of precision, the piezo is encapsulated with a special FERMASIL silicone foam to dampen the vibration impact.

The properties of FERMASIL silicone foams, tailored to requirements, are critical in ensuring reliable and functioning ultrasonic sensors.

Our fully automatic mixing and dosing systems ensure highly accurate processing and dosing of these.

Are you also faced with the task of encapsulating distance sensors with extreme accuracy in high quantities and at high process speeds with very small material quantities? We are able to do this with our dosing technology. Within the cycle times specified by our customers, we can apply even the smallest quantities with a highly repeatable accuracy of +/- 0.01 mm into the sensor housings.

Reliable ultrasonic sensors due to vibration damping

Optimally potted with special silicone foam

The distance sensors work according to the ultrasonic echolocation principle. The sensors emit short ultrasonic pulses that are reflected by obstacles. The echo signals are registered by the sensors and evaluated by a central control device. In this way, the sensitive systems of the sensors always provide the car’s on-board computer with accurate data.

The piezoelectric distance sensors offer the best conditions for generating and detecting the ultrasonic waves. The piezo actuator works as a transmitter and receiver. It emits an ultrasonic pulse that is reflected by an object or obstacle. The required travel time of the resonant frequency is a measure of the distance covered. The distance measurement is based on the travel time difference when ultrasonic pulses are alternately transmitted and received.

The piezo actuator is located on the cavity floor of the sensor housing and is potted with the two-component silicone foam FERMASIL A-33-4 and B-33-4 for vibration damping.

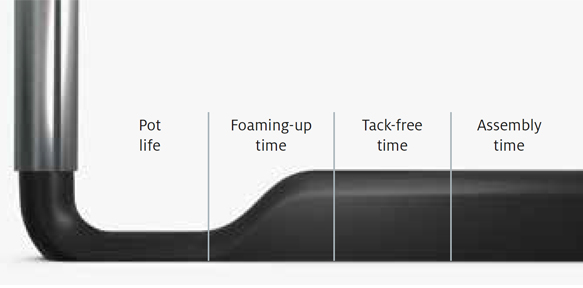

The various reaction phases of the sealing foam in chronological order.

After curing the silicone foam is characterized by a high level of elasticity, so that temperature differences from -60 to +180 °C can be met. FERMASIL is also weather-resistant and has very low water absorption levels thanks to its almost closed foam cell structure.

This is the perfect solution to keep the required properties of ultrasonic distance sensors consistent.

Reference material

| FERMASIL A-33-4 | |||

| FERMASIL B-33-4 | |||

|

Mixing ratio |

1 : 1 | ||

|

Pot life time |

280 sec. | ||

|

Tack-free time |

35 min. | ||

|

Viscosity A component |

9,000 mPas | ||

|

Viscosity B component |

5,200 mPas | ||

|

Density of the foam |

0.74 g/cm³ | ||

|

Hardness (Shore A) |

24 | ||

|

Temperature resistance |

from -60 to +180 °C |

The FERMASIL silicone foam is applied to the piezo in the ultrasonic distance sensor and ensures consistent vibration damping.

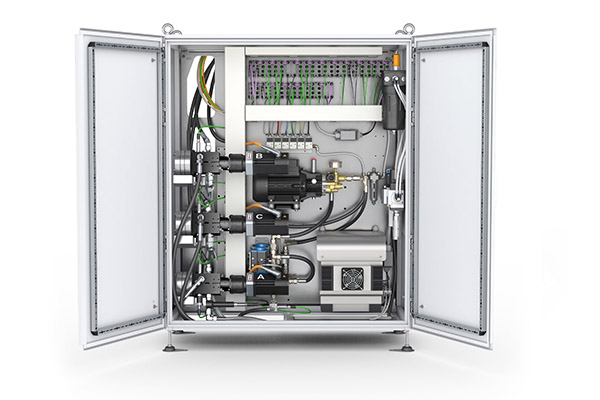

Customer-specific mixing and dosing systems for accurate and efficient dosing processes

Flexible and fully automatic – according to your requirements

As process experts, we support our customers with individual advice for the automation of your manufacturing processes. We offer numerous configuration and equipment options for semi-automatic or fully automatic production systems, using either the 3-axis linear robots or 6-axis robots.

The ultrasonic distance sensors are fed for the application of the sealing foam via a conveyor belt system that runs through the SMART-L dosing cell. The centering station positions the sensor housing for the dosing of the sensors with FERMASIL silicone foam.

Despite the usually high volumes of parts and process speeds, the dosing cell is able to dispense even the smallest quantities into the sensor housing via the MK 825 PRO precision mixing head with a positioning accuracy of +/- 0.01 mm, with high dosing accuracy and no deviations from the specified cycle times.The main focus of all our solutions is to ensure very reliable plant engineering, minimized maintenance times and consistent dosing quality. Due to the traceability of the dosing program data, all process data can be traced while production is running.

Control cabinet

Dosing machine cabinet

Material pressure tanks

MP 2 mobile panel

Mixing head 825 PRO

Control cabinet

Dosing machine cabinet

Material pressure tanks

MP 2 mobile panel

Mixing head 825 PRO

Control cabinet

The control electronics, safety engineering and industrial PC are installed in the control cabinet.

More information to our control cabinetsDosing machine cabinet

The dosing machine cabinet contains the components of the dosing periphery, e.g. the dosing pumps.

More information to our dosing machine cabinetsMaterial pressure tanks

Material pressure tanks (24 l or 44 l, single-walled or double-walled) with minimum level sensors, on a grating platform with adjustable leveling feet and drip tray

More information to our material Pressure TanksMP 2 mobile panel

The multifunctional MP 2 mobile panel (10.1” WXGA TFT) enables convenient operation of the dosing system.

More information to our operating panelsMixing head 825 PRO

MK 800 PRO precision mixing head with high-pressure water rinsing or alternative component rinsing system

More information to our mixing heads