Polyurethane gel with self-healing effect and airtight closure

The requirements for sealing material used in panel filters for air conditioning systems in hospitals, and clean rooms for microchip manufacturing, are challenging. State-of-the-art production processes, such as those in the pharmaceutical and microelectronics industries, also require high levels of air purity.

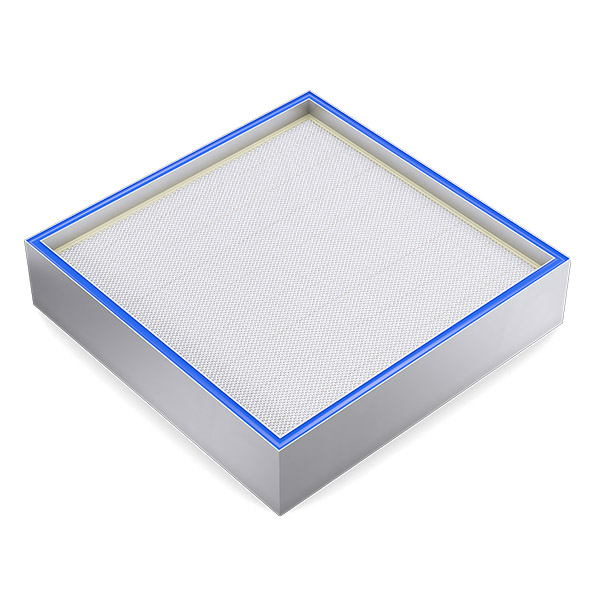

The air filters required for clean rooms, from HEPA (High Efficiency Particulate Air) to super ULPA (Ultra-Low Penetration Air) filters, not only need to be manufactured to the highest quality standards but also require a leak-free fit when installed. This is ensured by FERMADUR gel seals.

With the help of the very precise DM 502 mixing and dosing machine, the gel seals are injected bubble-free into the groove of the filter frames. They are also available in low Shore hardness versions. The high aging resistance of the gel seals excludes the possibility of leakage, or of the filter seals losing tension over time.

Animation of sealing and bonding of panel filter frames with Sonderhoff DM 50x

Gel sealing of panel filter frames

The reference material presented here is a 2-component polyurethane gel FERMADUR A-112-VP3 with the crosslinker FERMADUR B-50-NM as B-component. It has been used for sealing panel filter frames by leading manufacturers of air filters for many years, and is tried and tested. Alternatively, we can also customize our material systems to meet your specific component requirements.

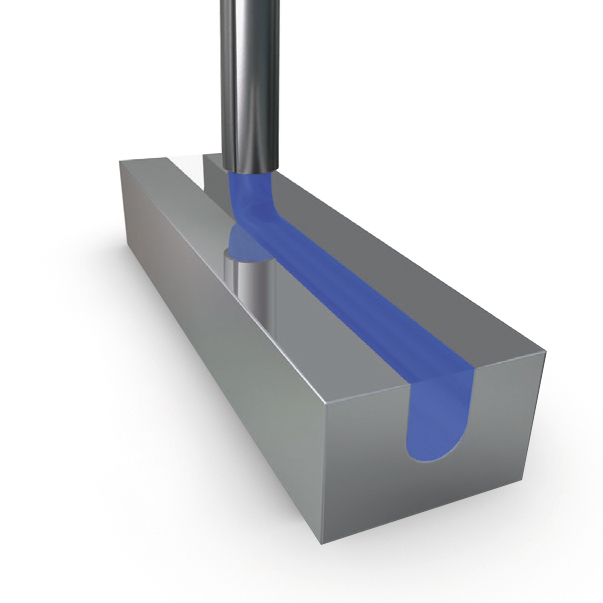

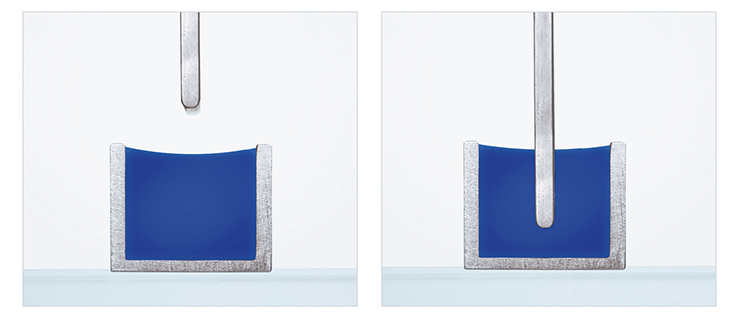

During installation in e. g. an air-conditioning system using the tongue-and-groove principle, the panel filter frame is installed with the tongue of the counterpart immersed in the gel seal. This creates an airtight seal.

The decisive factor is that when the filter frame is removed for maintenance purposes, the place where the tongue was immersed in the gel will reliably close again of its own accord, thanks to the self-healing effect. The filter seat is thus hermetically sealed, and all air flows through the filter without air impurities being able to get past the filter into the conditioned room air.

Cross-section: Tongue immersed in polyurethane gel seal

The different reaction phases of the sealing foam in the chronological sequence

Reference material

| FERMADUR A-112-VP3 | ||

| FERMADUR B-50-NM | ||

| Mixing ratio | 6 : 1 | |

| Pot life time | 200 sec. | |

| Tack-free time | permanently gel-like | |

|

Viscosity of the A component |

200 mPas | |

| Density of foam | 1,02 g/cm³ | |

| Hardness (Shore 00) | 15 | |

| Temperature resistance | from -40 to + 80 °C |

In addition to the reference products, we develop material systems according to your individual requirements. Influencing factors include pot life until start of foaming, curing time, and the viscosity, hardness and adhesion properties.

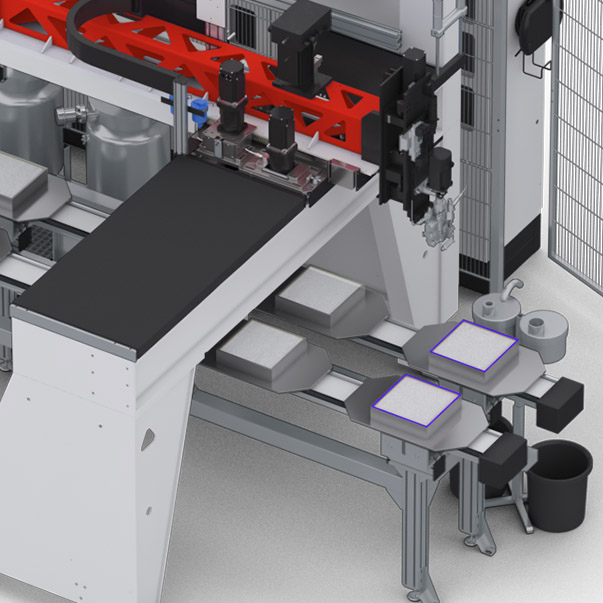

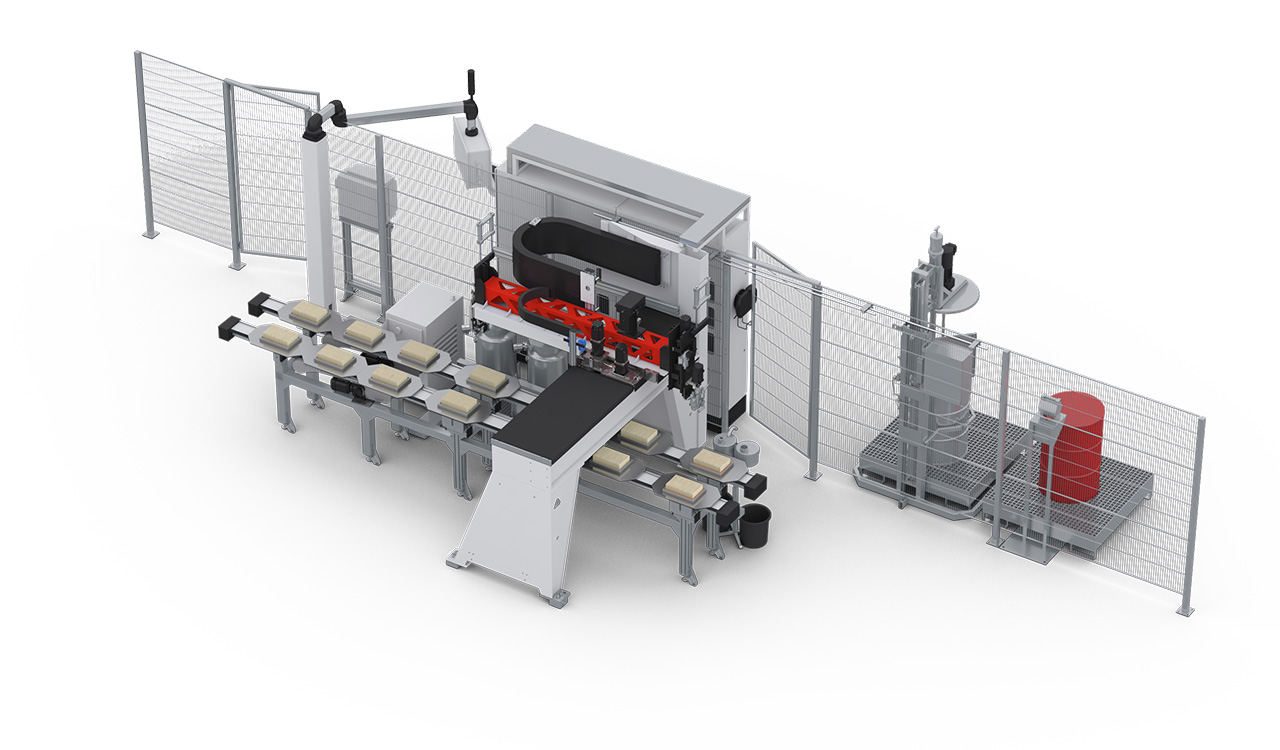

Mixing and dosing system DM 502 with 3-axis linear robot for the sealing of panel filter frames using sealing foam or gel seals

Flexible and fully automatic – fully in line with your requirements

In the reference configuration of the DM 502 mixing and dosing system shown here, the filter frames are fed to the dosing station on a transfer belt passing under the 3-axis linear robot.

The highly dynamic LR-HD 3-axis linear robot handles the contour-accurate CNC-controlled movement of the precision mixing head above the component.

Alternatively, the DM 502 can also be used as a sliding table system with the LR-HD linear robot and the WT 1-LEVEL shuttle table.

The MK 800 PRO precision mixing head of the DM 502 applies the polyurethane gel seal into the frame groove contour fully automatically using the FIPFG process with high dosing and repeat accuracy.

FERMADUR A-112-VP3 is used for the application of the polyurethane gel seal in the frame groove.

For a comprehensive filter product portfolio, the DM 503 mixing and dosing unit, designed for three components, can alternatively be used to produce panel filters with a groove design with two different sealing systems using the same dosing unit.

The applied material forms an elastic soft foam seal of the desired hardness at room temperature. It achieves a consistently high level of sealing with the tongue-and-groove principle.

The fail-safe DM 502 mixing and dosing machine can be operated easily and intuitively without much training.

The dosing and process data are recorded, and can thus be tracked and evaluated by the machine operator via the CONTROL 2 operating panel.

Elevator

Supply Tap

Mixing head 825 PRO

Control cabinet

Dosiermaschinenschrank

CONTROL 2

MP 2 Mobile panel

Elevator

Supply Tap

Mixing head 825 PRO

Control cabinet

Dosiermaschinenschrank

CONTROL 2

MP 2 Mobile panel

Elevator

Optional: Automatic ELEVATOR drum refilling station for the A-component with pneumatic lift and agitator

Mehr Informationen zu unseren NachfüllstationenSupply Tap

Optional: Automatic SUPPLY TAP drum refilling station for low-viscosity products, e.g. isocyanate (B-component)

Mehr Informationen zu unseren NachfüllstationenMixing head 825 PRO

MK 800 PRO precision mixing head with high-pressure water rinsing or alternative component rinsing system

More information to our mixing headsControl cabinet

The control electronics, safety engineering and industrial PC are installed in the control cabinet.

More information to our control cabinetsDosiermaschinenschrank

The dosing machine cabinet contains the components of the dosing periphery, e.g. the dosing pumps.

More information to our dosing machine cabinetsCONTROL 2

Optionally available: CONTROL touchscreen operating panel (21.5“) for operating the dosing system

More information to our operating panelsMP 2 Mobile panel

The multifunctional MP 2 mobile panel (10.1” WXGA TFT) enables convenient operation of the dosing system.

More information to our operating panels