High performance filter systems play a hidden but important role in our modern world. These include systems for industrial plants, hospitals and power stations which often have to deliver consistently clean air under tough operation conditions. Reliable air conditioning technology with purified air ensures the smooth operation of technical facilities in the research, IT infrastructure and production sectors.

Air conditioning systems provide indoor spaces with filtered fresh air, creating a healthy indoor climate. This is important for our personal well-being, as well as compliance with regulations for ensuring air quality in workplaces, offices and production facilities. It is a matter of constantly exchanging air in rooms and removing humidity, odors, smoke, carbon dioxide, heat accumulation, dust or airborne bacteria.

To ensure that the air filters can perform these tasks for air conditioning in the office, clean rooms in laboratories and operating theaters, optimal bonding of the filter pack into the frame is essential. The fresh air pumped in to be cleaned flows exclusively through the filter medium and requires a leak-free sealing of the filter frame in its installed state.

Are you looking for a system solution consisting of sealing material, dosing system and process automation from a single supplier?

We offer you a perfectly coordinated sealing and bonding solution, which will optimally and reliably enable you to meet your various technical and economic requirements. Irrespective of whether they are compact; pocket; cartridge or panel filters; filter end caps or filter cassettes, leading manufacturers have been relying on our expertise for decades. In each case they have used out sealing and bonding solutions to implement the best possible filter production process.

Do you need an automation system that adapts to your production requirements?

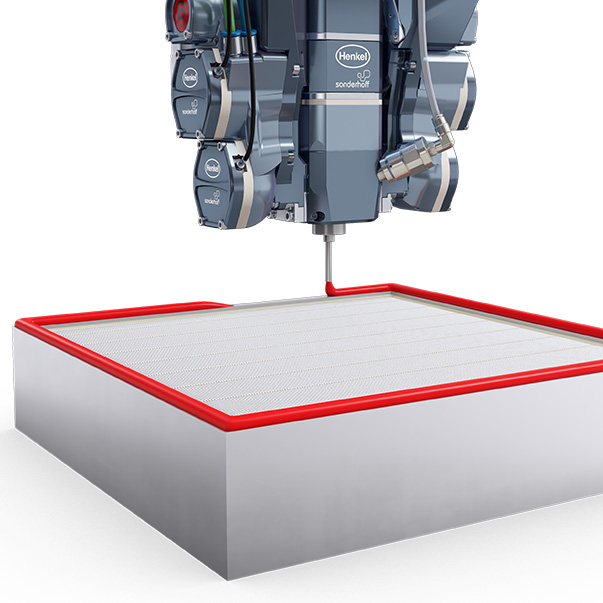

The modular design of our mixing and dosing systems allows flexible use, with excellent integration into existing production concepts. Our CNC-controlled mixing and dosing systems offer high levels of repeatability and dosing accuracy and are highly efficient.

Henkel’s technology solutions are designed to optimize the quality, reliability and safety of your filter products in use.

Moreover, Henkel’s molding and sealing foams and adhesive sealants ensure that the filters deliver what they promise: clean air.

Sealing, bonding and potting out of one hand

With the SONDERHOFF portfolio, you get everything from a single source, from material systems to mixing and dosing systems to contract manufacturing.

As a process expert, we offer OEMs and suppliers individual consulting for automation and application technology. Our material solutions with different properties include foam gaskets based on polyurethane or silicone as well as systems for bonding and potting. We support you with application engineering advice from the component design phase to fully automated material application using FIPFG technology.

Alternatively, with our contract manufacturing service, you get the option of us taking over the sealing, bonding or potting of your components directly for you, from the sampling of prototypes and small series to large-scale production.

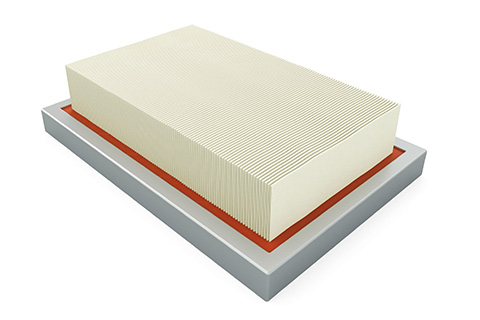

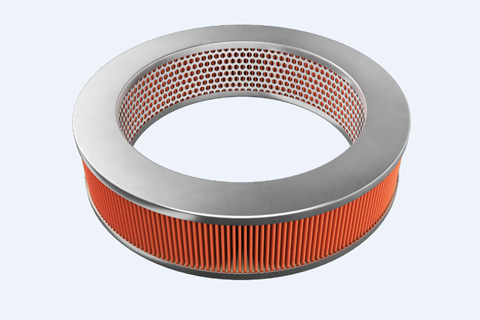

Air filter with molded foam sealing

A wide range of technically reliable solutions for automotive air filters can be achieved by foam-in-place gaskets with the reference material FERMAPOR-K31-A-9846-12-VP2 and B-81 (B-component) made of -component polyurethane foam. By using an open mold into which the sealing material is introduced, square air filter frames can be produced, or even round shapes like e. g. the end caps on radial filters for commercial vehicles.

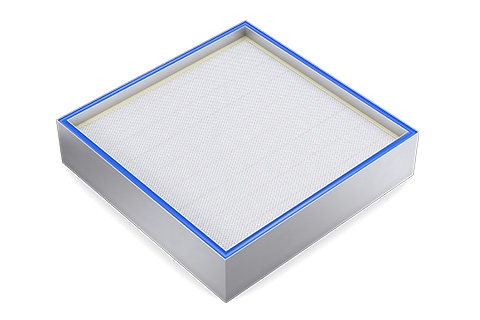

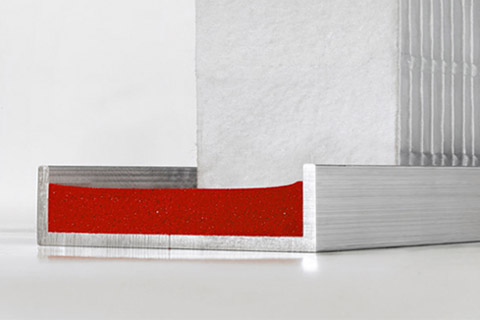

Sealing of panel filter frames

The reference materials presented here have been used by leading manufacturers of panel air filters for many years, and are tried and tested. The 2-component polyurethane sealing foams of the FERMAPOR K31 product family are available for this purpose in different viscosities, ranging from liquid for the frame groove to thixotropic for flat or three-dimensional application surfaces. The thixotropic sealing foams are available in a soft and also slightly harder versions.

Gel sealing of panel filter frames

The reference material presented here is a 2-component polyurethane gel FERMADUR A-112-VP3 with the crosslinker FERMADUR B-50-NM as B-component. It has been used for sealing panel filter frames by leading manufacturers of air filters for many years, and is tried and tested. Alternatively, we can also customize our material systems to meet your specific component requirements.

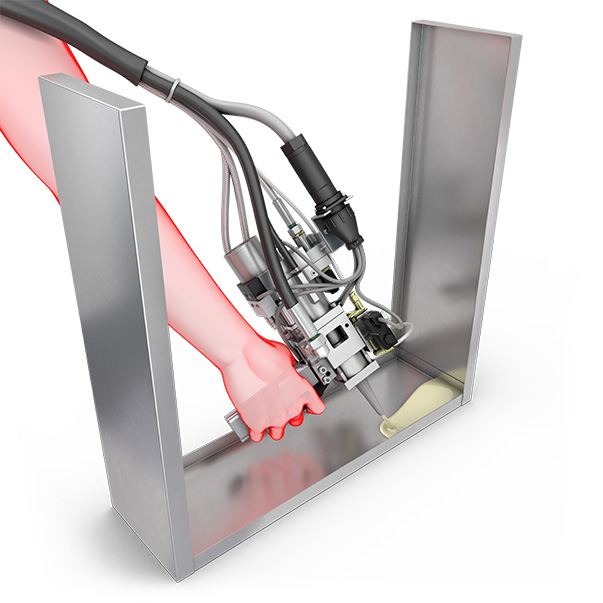

Bonding of filter packages in frames or end caps

For purposes of bonding filter packs into filter frames or to the end caps, the compact, polyurethane-based 2-component adhesive sealant systems FERMADUR A-46D05-1-W or FERMADUR A-196-9-VP1 are available, each with the B-component FERMADUR-B-N.

The reference materials presented here have been used by the leading manufacturers of air filters for many years, and are tried and tested.

Foamed Filter Adhesive

The foamed filter adhesive from the range of SONDERHOFF FERMADUR adhesive sealant systems, bonds the filter package to the filter frame. Due to the foamed cell structure, this filter adhesive has a lower density. The amount of adhesive per filter can therefore be reduced by up to 50 percent. This enables a high degree of economic efficiency in filter production.