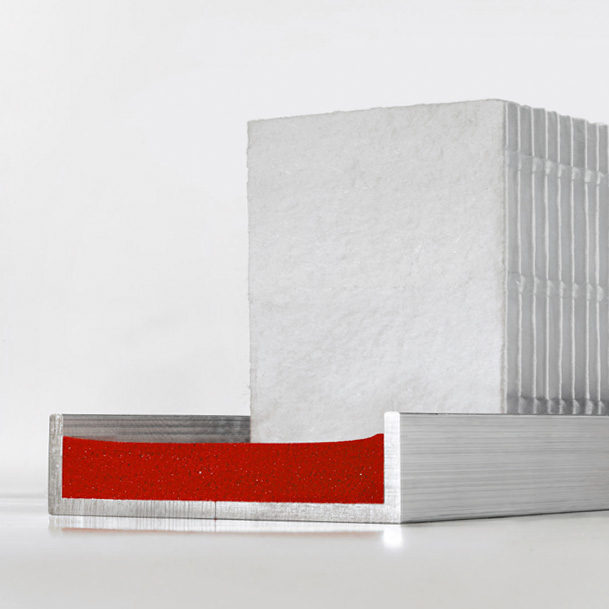

Higher efficiency due to foamed filter adhesive

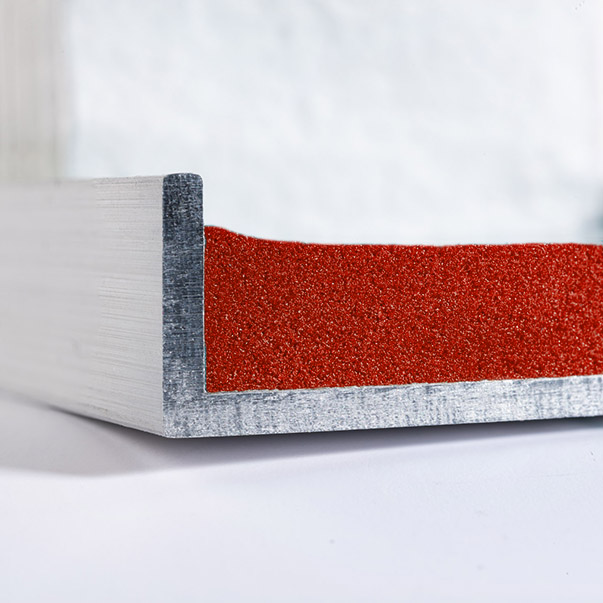

The foamed filter adhesive from the range of SONDERHOFF FERMADUR adhesive sealant systems, bonds the filter package to the filter frame. Due to the foamed cell structure, this filter adhesive has a lower density. The amount of adhesive per filter can therefore be reduced by up to 50 percent. This enables a high degree of economic efficiency in filter production.

The lower weight also makes easier part handling possible. Both features save money, while still meeting the requirements for high-quality filter bonding.

Not only the right choice of raw materials is decisive for a consistently high quality in sealing and bonding filters, but above all the safety and accuracy of the production plant. The SONDERHOFF mixing and dosing systems from Henkel stand for a safe and precise application process of 2-component reaction materials.

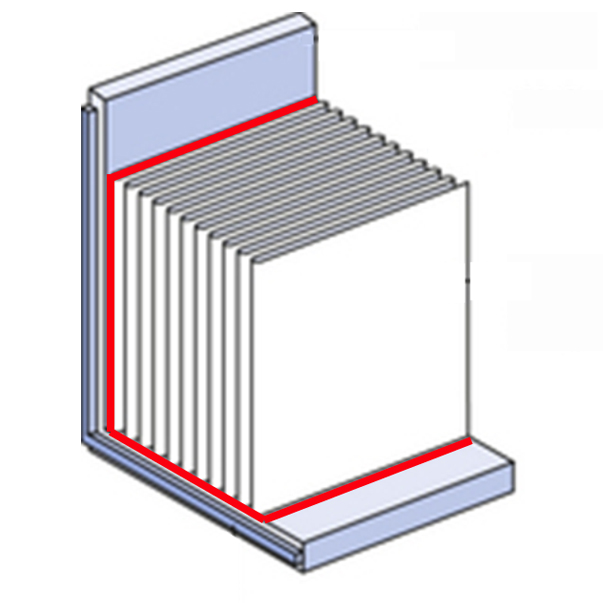

Using the Formed-In-Place (Foam-Gasket) (FIP/FIPFG) technology established in the filter industry, the 2-component adhesive sealant is applied directly to the filter components via the mixing head in a fully automatic and process-safe manner and then foams up. In addition, the good flow properties of SONDERHOFF FERMADUR adhesive sealants ensure a full-surface adhesive application to the inside of a filter frame. The pleated filter placed in the filter frame is thus sealed airtight on all sides.

SONDERHOFF FERMADUR adhesive sealants cure at room temperature. This saves the costs for a tempering oven, which must be used for other processes. The components can therefore be processed quickly.

SONDERHOFF seals meet high sealing equirements

Filter packs must be well bonded into the inner frame and the filter frames must ensure a perfect seal to the counterpart using the tongue-and-groove principle, so that no air passes the filter unfiltered. Henkel offers the filter industry the appropriate SONDERHOFF material systems and dosing equipment with FIP(FG) technology for this purpose.

The 2-component material systems based on polyurethane or silicone cover the application spectrum from vacuum cleaner filters to automotive and air filters. Special formulations meet the quality requirements of VDI 6022 for use in filters in ventilation and air conditioning systems in hospitals and for chip production in clean rooms.

Special properties for special requirements

Special polyurethane-based material systems also offer protective functions such as low-emission for low VOCs (Volatile Organic Compounds) in the indoor air, antifungal or antibacterial properties or flame retardancy in accordance with UL 94 V-2 for sealing foams or UL 94 V-0 for adhesive sealants. Temperature-resistant silicone foams of the product systems SONDERHOFF FERMASIL are used for sealing air filters in the engine compartment at high temperatures.

The foamed filter adhesives from the SONDERHOFF FERMADUR adhesive sealant systems with up to 50 % less material consumption are an innovative example of increased efficiency in the production of various filter applications.

Reference material

| FERMAPOR K31- | A-20D01-1 |

| B-N | |

|

Mixing ratio |

1,9 : 1 |

|

Pot life time |

30 sec. |

|

Tack-free time |

3 min. |

|

Viscosity of the A component |

500 mPas |

|

Density of foam |

0.56 g/cm³ |

|

Hardness (Shore D) |

30 |

|

Temperature resistance |

from -40 to + 80 °C |

| Pretreatment | if necessary, plasma, corona, flame or primer |

In addition to the reference products, we develop material systems according to your individual requirements. Influencing factors include pot life until start of foaming, curing time, and the viscosity, hardness and adhesion properties.