Sealing, bonding and potting systems for high-quality household appliances and “white goods” have to satisfy a wide range of requirements that make a decisive contribution to functionality, safety and user satisfaction. Foam gaskets, for example, must be watertight when installed, withstand a high temperature range and be resistant to the chemical constituents of washing and cleaning products over the long term.

The leading manufacturers of household appliances have relied on our Formed-In-Place Foam Gasket (FIPFG) sealing technology and wide range of sealing foam systems for many years.

The optimally matched material and dosing machine systems ensure precise and efficient sealing. Dishwashers and washing machine components are sealed through an application of process-stable foam that is controlled by contour robots. Frames of glass ceramic cooktops are fitted with foam gaskets to seal the installed appliance tightly within the kitchen countertop.

It does not matter whether your product is manufactured from plastic, glass-ceramic, stainless steel, or anything else, we tailor the formulation of our foam gasket systems specifically to provide the characteristics you require. The diversity of our solutions especially when it comes to developing new designs while protecting device electronics reliably.

Are you looking for a complete system solution to seal your household applications from a single source?

We offer you a perfectly matched sealing solution consisting of a foam gasket material, dosing system and automation. You will get a fully automatic material application and high-precision dosing controlled by contour robots. This will enable you to meet your various technical requirements optimally and reliably.

Do you need an automation system that adapts to your production requirements?

The modular design of our mixing and dosing systems with their peripheral interfaces allows flexible and efficient use and excellent integration into existing production concepts. In addition, our dosing systems are very easy and intuitive to operate offering a continuous process monitoring.

Our solutions provide you exactly the levels of durability, quality and reliability that your customers expect from your products.

Sealing, bonding and potting out of one hand

With SONDERHOFF SYSTEM SOLUTIONS (S3), you get everything from a single source, from material systems to mixing and dosing systems to contract manufacturing.

As a process expert, we offer OEMs and suppliers individual consulting for automation and application technology. Our material solutions with different properties include foam gaskets based on polyurethane or silicone as well as systems for bonding and potting. We support you with application engineering advice from the component design phase to fully automated material application using FIPFG technology.

Alternatively, with our contract manufacturing service, you get the option of us taking over the sealing, bonding or potting of your components directly for you, from the sampling of prototypes and small series to large-scale production.

Sealing of detergent tab housings in dishwashers

Our reference material FERMASIL is a room-temperature-curing 2-component silicone foam for the sealing of detergent tab housings in dishwashers and has already proven itself in many years of use by leading appliance manufacturers. The silicone sealing foam is applied directly to the component using FIPFG (Formed-In-Place-Foam-Gasket) technology and our fully automated dosing machines, very precisely, safely and efficiently.

Sealing dirt traps in dishwashers

Our reference material FERMAPOR K31 is a room-temperature-curing 2- component polyurethane foam for the sealing of dirt traps in dishwashers and has already proven itself in many years of use by leading appliance manufacturers. The polyurethane sealing foam is applied directly to the component using FIPFG (Formed-In-Place-Foam-Gasket) technology and our fully automated dosing machines, very precisely, safely and efficiently.

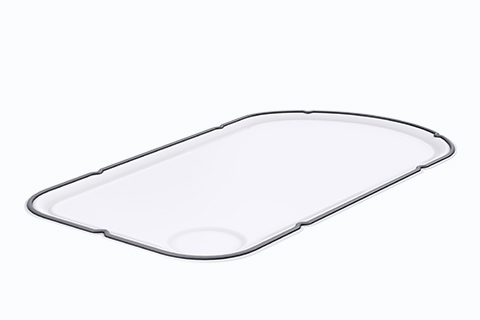

Sealing of service panel in the washing machine rear wall

Our reference material FERMAPOR K31 is a room-temperature-curing 2- component polyurethane foam for the sealing of service panels in washing machine rear walls. It has already proven itself in many years of use by leading appliance manufacturers. The polyurethane sealing foam is applied directly to the component using FIPFG (Formed-In-Place-Foam-Gasket) technology and our fully automated dosing machines, very precisely, safely and efficiently.

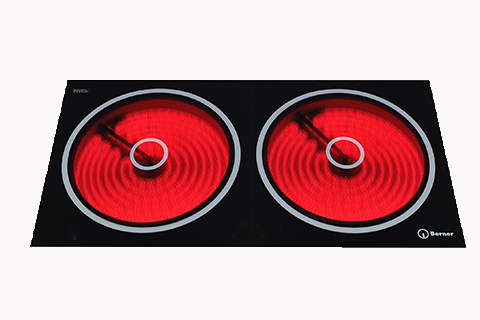

Sealing solutions for glass ceramic cooktops

Our reference materials FERMAPOR made of polyurethane and FERMASIL made of silicone, are room-temperature-curing 2-component sealing foams for sealing the frames of glass ceramic cooktops. They have already proven themselves in many years of use by leading appliance manufacturers.