Optimal bonding of glass doors in ovens

Ovens have become indispensable in modern kitchens. The functionality and safety of these appliances depend heavily on the quality of their components and workmanship, as well as optimal bonding and sealing.

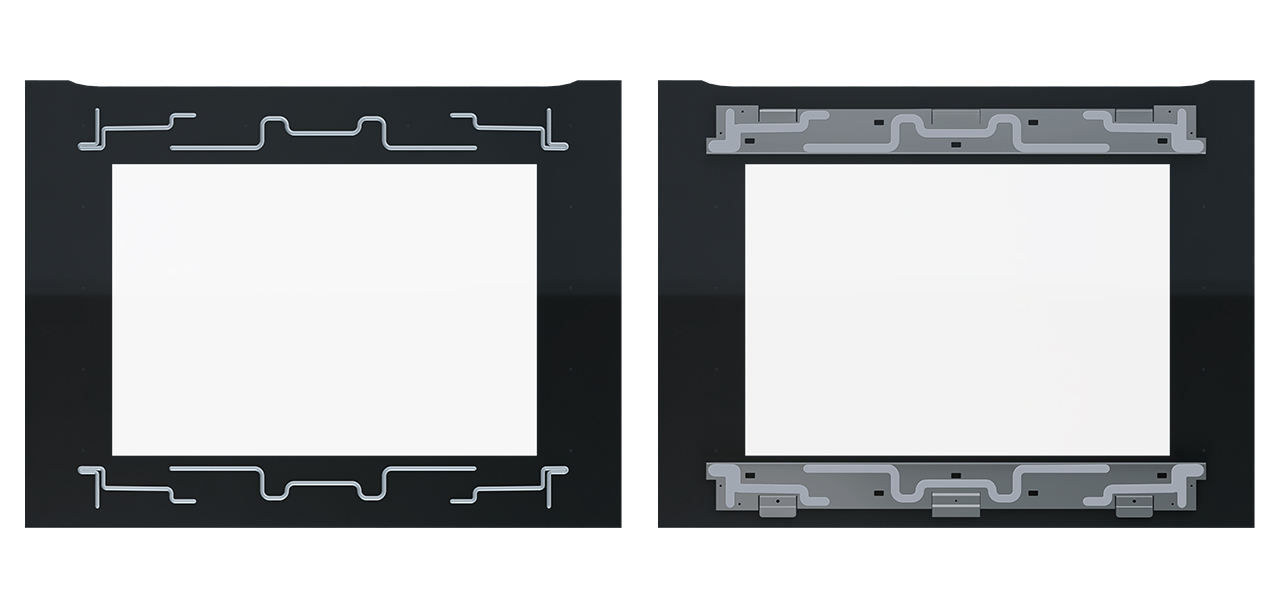

In ovens, the glass door is both a design and functional element. Brackets are bonded to the glass door inside with a structural adhesive from Henkel to attach the door frame, which holds the inner glass pane inserted there.

The heat-resistant glass of the door not only provides a clear view of the cooking or baking process but is also an essential part of the safety mechanism of ovens.

Whatever the material of your product, from plastic to glass ceramic to stainless steel, we offer a wide range of innovative structural adhesives with a variety of properties.

Are you looking for a complete system solution for bonding glass doors of oven from a single source?

We can provide you with an optimally coordinated system solution consisting of adhesive, dosing system and process automation. It offers fully automatic material application and high-precision dispensing controlled by contour robots. This allows you to meet your various technical requirements optimally and reliably.

Our system solutions give you exactly the longevity, quality and reliability that your customers expect from your products.

Customized adhesive solutions for oven doors

LOCTITE® 2-component silicone structural adhesives for bonding brackets to the inside of the oven door

For bonding metal brackets to the inside of oven doors, we recommend LOCTITE® SI 5610 A/B.

It is a 2-component fast cure silicone structural adhesive used in high temperature applications, resistant up to 180 °C and higher temperatures for short-term exposure. The metal brackets are bonded for fixing a support frame for the inner glass pane of the oven doors.

The dosing application takes place within the pot life of approx. 2 to 3 minutes. Due to the fast-setting time of LOCTITE® SI 5610, the oven doors can already be assembled approximately 3 minutes after application.

LOCTITE® SI 5610 with excellent adhesion to metals and Ceran® glass generally does not require primer pretreatment of the bonding surfaces but should always be tested in specific cases.

In addition, we offer a wide range of structural adhesives with different properties for other applications in this field.

Reference material

|

LOCTITE® SI 5610 A/B |

||

|

Mixing ratio (by weight) |

2 : 1 | |

| Pot life (A + B mixed) | 2-3 min. | |

|

Adhesive release time at 23 °C / |

≤ 6 min. | |

|

Curing at ambient temperature |

approx. 30 min. |

|

|

Viscosity A-Component |

approx. 20,000 - 100,000 mPa·s |

|

|

Viscosity B-Component |

approx. 10,000 - 80,000 mPa·s |

|

|

Shore-A-Hardness (ISO 868) |

approx. 30 - 50 |

|

|

Elongation at break (ISO 527-3) |

210 % |

|

| Tensile strength (ISO 527-3) | approx. 1.35 (200 psi) | |

|

Service temperature |

from -40 to +180 °C (short term higher) |

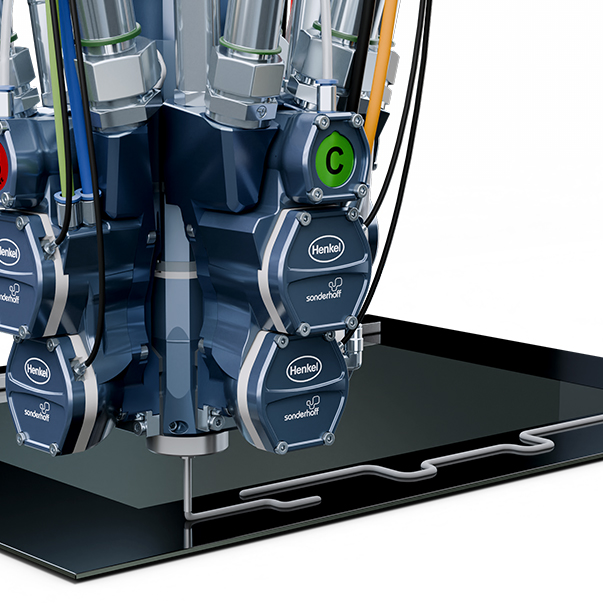

Structural adhesive application with precision mixing head MK 825 PRO

The silicone structural adhesive LOCTITE® SI 5610 A/B for bonding the metal brackets is applied directly without primer on the inside of the glass door using FIP (Formed-In-Place) technology and our fully automatic dosing machines – very precisely, safely and efficiently.

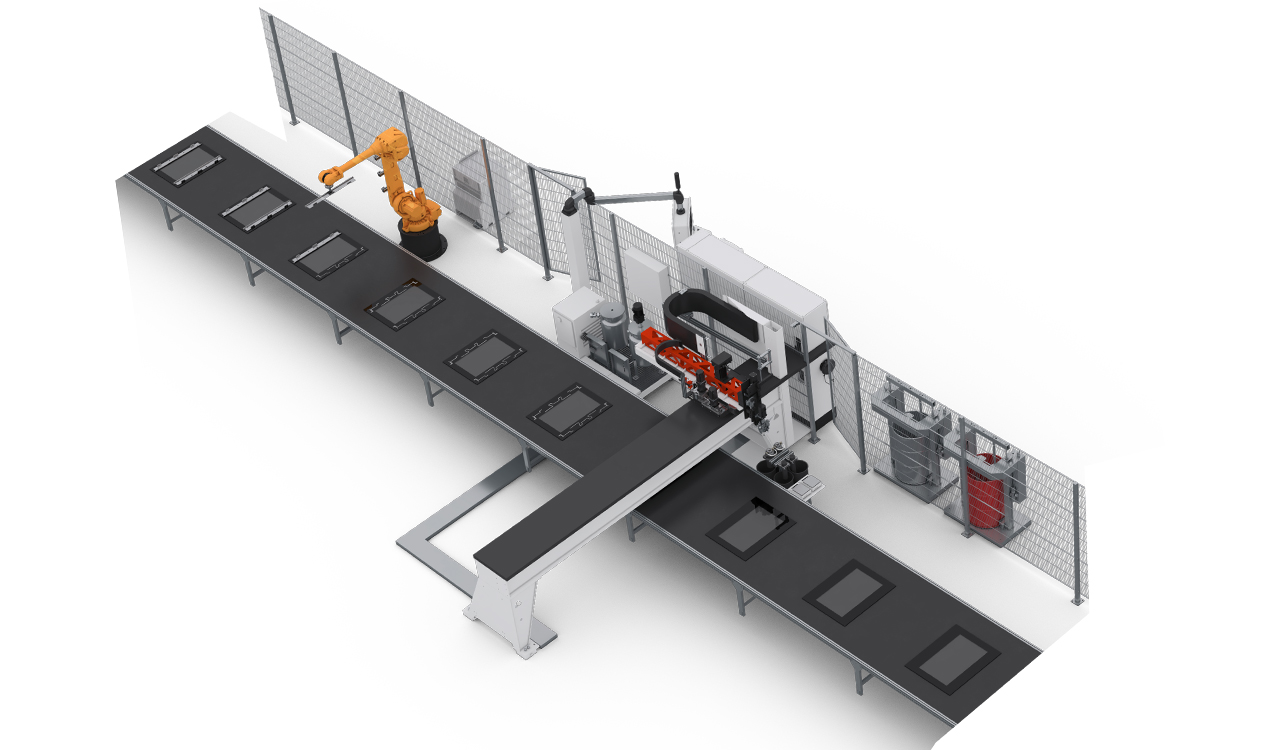

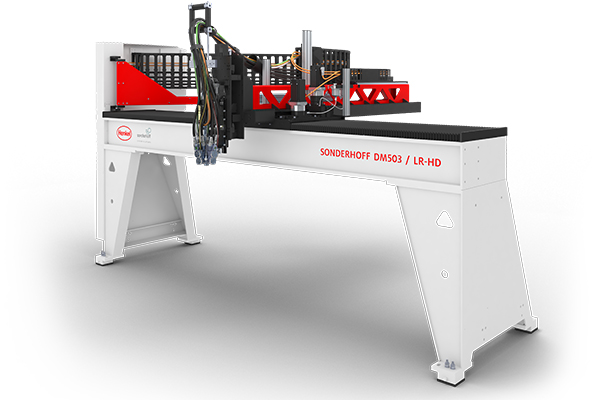

DM 502 mixing and dosing system with 3-axis linear robot for adhesive application for bonding metal brackets on the inside of oven doors

Flexible and fully automatic – according to your requirements

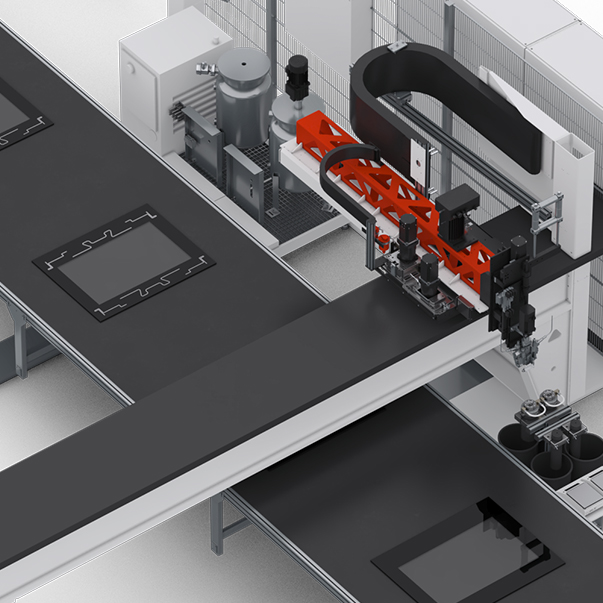

The reference configuration shown here is used for the precise, fully automatic application of the LOCTITE® 2K structural adhesive for bonding metal brackets to the inside of oven doors.

It consists of the DM 502 mixing and dispensing system with the LR- HD 3-axis linear robot and a transfer belt for feeding and removing parts.

The oven doors are fed to the dosing station on the transfer belt in the cycle specified for your production. The LOCTITE® 2K structural adhesive used is applied there by the 3-axis linear robot-controlled mixing head 825 PRO to the application areas on the inside of the oven door intended for bonding the metal brackets.

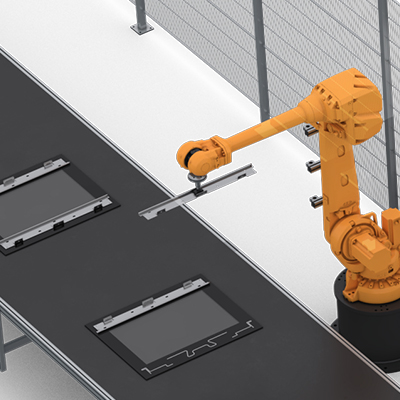

In the next step, the 6-axis robot joins the metal brackets with the LOCTITE® adhesive beads.

The highly dynamic LR-HD 3-axis linear robot ensures exact guidance of the MK 825 PRO precision mixing head over the part.

An alternative process option to the transfer belt is to feed and discharge parts using the WT 1-LEVEL shuttle table (as shown in the previous reference configuration).

Our mixing and dosing machines can be operated easily and intuitively without the need for extensive training. The automatic recor- ding of dispensing program data means that the machine operator can track and evaluate all process data via the CONTROL 2 operating panel while production is running.

With all solutions, our focus is on highly reliable system technology, minimized maintenance times and consistent dosing quality. As process experts, we support you with customized advice for the automation of your production processes.

Mixing head 825 PRO

MP 2 mobile panel

Material pressure tanks

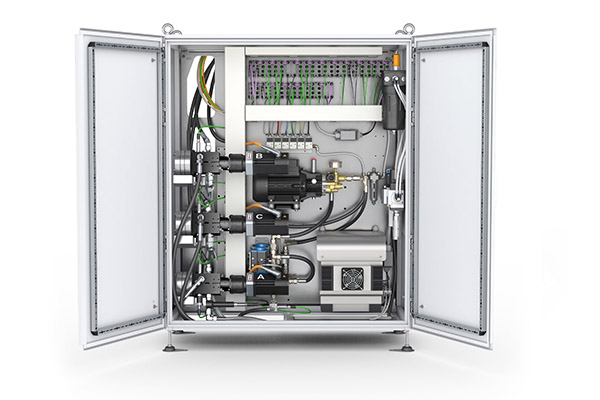

Dosing machine cabinet

Control cabinet

CONTROL 2

FPS

Linear robot LR-HD

6-axis robot

Mixing head 825 PRO

MP 2 mobile panel

Material pressure tanks

Dosing machine cabinet

Control cabinet

CONTROL 2

FPS

Linear robot LR-HD

6-axis robot

Mixing head 825 PRO

MK 825 PRO precision mixing head with high-pressure water rinsing or alternative component rinsing system

More information to our mixing headsMP 2 mobile panel

The multifunctional MP 2 mobile panel (10.1” WXGA TFT) enables convenient operation of the dosing system.

More information to our operating panelsMaterial pressure tanks

Material pressure tanks (24 l or 44 l, single-walled or double-walled) with minimum level sensors, on a grating platform with adjustable leveling feet and drip tray

More information to our material Pressure TanksDosing machine cabinet

The dosing machine cabinet contains the components of the dosing periphery, e.g. the dosing pumps.

More information to our dosing machine cabinetsControl cabinet

The control electronics, safety engineering and industrial PC are installed in the control cabinet.

More information to our control cabinetsCONTROL 2

Optionally available: CONTROL touchscreen operating panel (21.5“) for operating the dosing system

More information to our operating panelsFPS

Optional for A- and B-material component: automatic barrel-type pump station for 30 to 200 liter containers, with scoop piston pump, as twin-column lifting unit, for highly viscous / pasty materials

More information to our refilling stationsLinear robot LR-HD

Highly dynamic 3-axis linear robot LR-HD for the precise guidance of mixing heads for the application of polymer reaction materials. The rack and pinion drive with high rigidity and acceleration enables dynamic application speeds.

More information to our linear robots6-axis robot

The 6-axis robot joins the metal brackets for attaching a holding frame to the inside of the oven glass door

More information to our 6-axis robots