Foam sealing with FIPFG technology

The industry standard for many sectors

Foam sealing with FIPFG (Formed-In-Place-Foam-Gasket) technology is significantly more efficient and economical than conventional insert seals (EPDM, TPE, NBR).

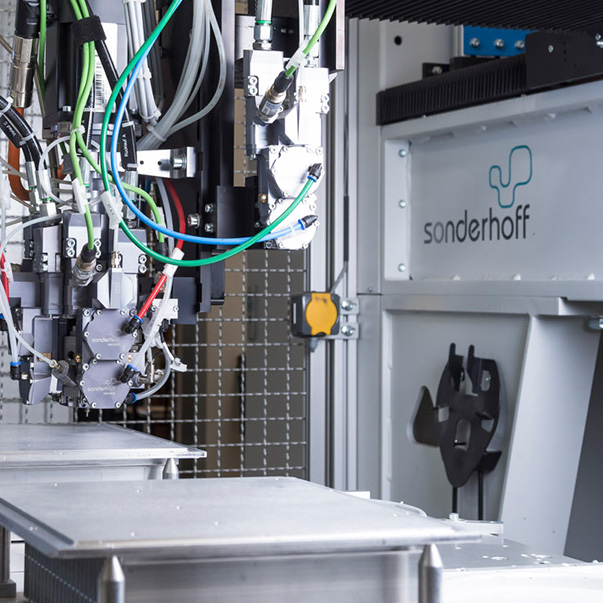

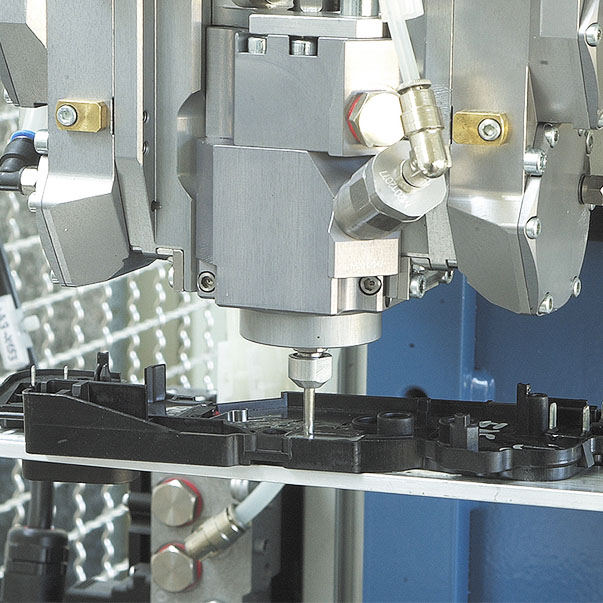

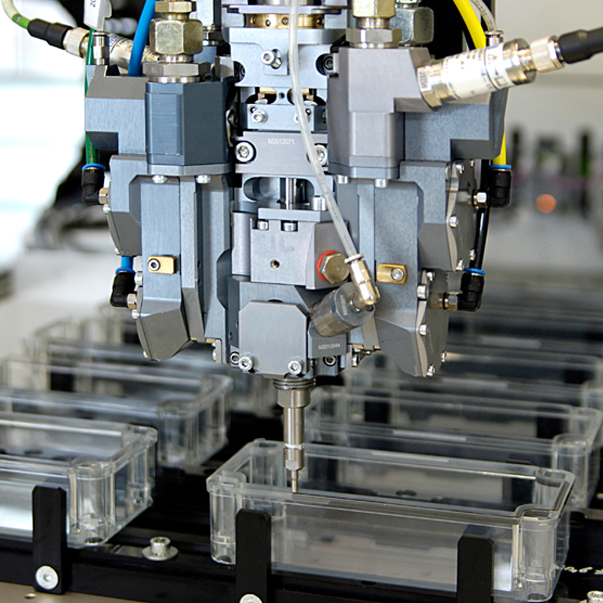

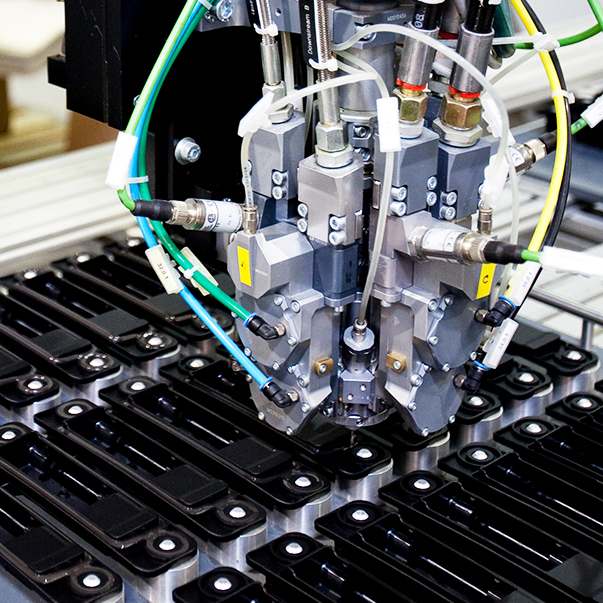

The fluid or thixotropic two-component sealant is applied directly (“in place”) to the component via a usually movable mixing head of the SONDERHOFF mixing and dosing machine, where it reacts at room temperature to form a soft sealing.

From natural to synthetic sealing

Mankind has been capable of sealing of joints and gaps for many centuries, e.g. when caulking ships’ planks. Beeswax, tree resin or tar was used.

The story of modern sealants starts with polymer chemistry in the 1930s and the development of synthetic plastics and sealants. And the history is still being written. Today a multitude of different materials and technologies is available for sealing components.

For modern industrial production, another crucial requirement has been set: the sealing process must ideally be fully automated. This automated sealing process for the application of foam gaskets is generally known as FIPFG technology (Formed-In-Place-Foam-Gasket).

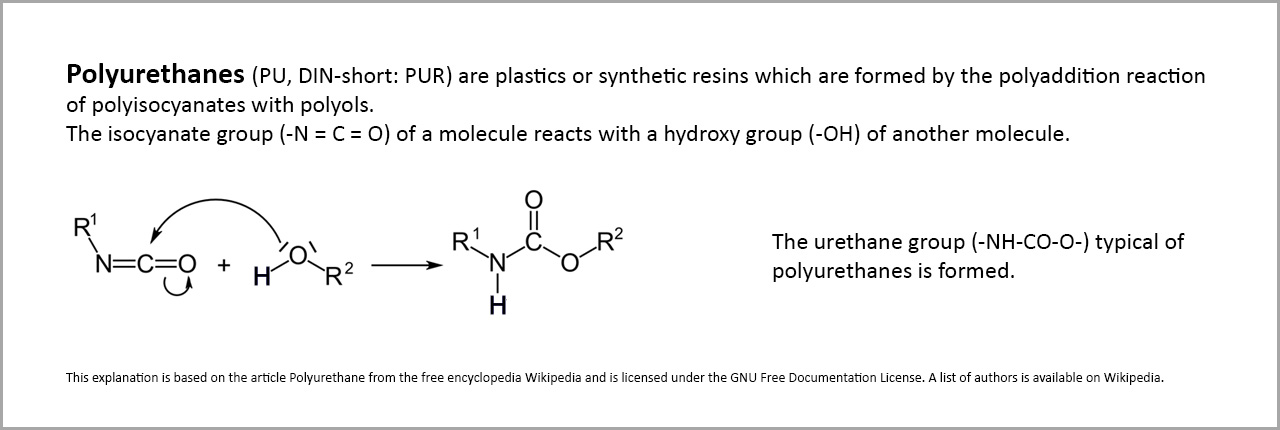

The chemistry makes it possible

Polymerising substances

The reaction substances in SONDERHOFF products from Henkel consist of a fluid to paste-like A-component (polyol) with varying molecular chain lengths for soft and hard foams and a hardener, the B-component (MDI). The polyurethane material systems are grouped under the brand name of FERMAPOR K31. Silicone-based products are branded with the name FERMASIL

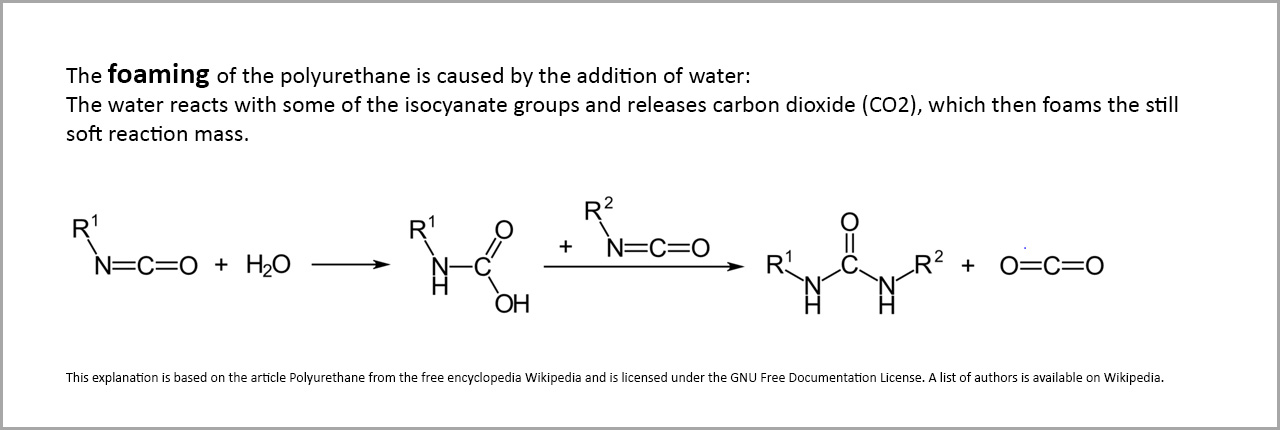

A polymer is a material whose molecules are made up of chains of monomer units. The longer the molecule chains of the polyol (A-component), the more flexible the soft foam. Through a chemical reaction with water and the hardener (B-component) a cross-linked structure of molecule chains is formed. During this process, carbon dioxide is produced as a spin-off product, which is responsible in the low-pressure process for the foaming of the material. A soft foam seal is formed which cures at room temperature, without the use of a tempering furnace.

2-Component material systems

The A-component (polyol) determines the chemical and physical properties of the sealing foam. The B-component (isocyanate) initiates the chemical reaction and influences above all the reaction speed. That is why we speak of “2K” or 2-component material systems. The mixing ratio of A and B-components plays a vital role here.

Approximately 90 % of the foam sealing systems are 2K polyurethane (PUR) material systems, which are developed with the use of polyurethane polyols. This substance is particularly versatile in its uses.

According to the choice of polyol and isocyanate, polyurethanes can have the widest variety of attributes. Depending on chain length and branching in the polyol, the mechanical properties can be positively influenced.

Silicone is used primarily if a high resistance to chemicals, solvents, very high temperatures and atmospheric influences is required.

Pot life and expansion time

Pot life

The duration of workability in a reactive substance is known as its pot life. In foam sealing it is the time spent mixing A with B components in the mixing chamber before dispensing it on to the part. Figuratively speaking it is the period in which the substances can still be taken out of the “pot” and processed. Usually the end of the pot life is signalled by a marked increase in viscosity, preventing further processing. The length of the pot life depends on the chemical properties of the components used and on the environmental conditions.

Thus giving the pot life of a substance only makes useful sense if the quantity, amount of mixing, surrounding climate (temperature and humidity) and vessel shape are also given.

Expansion time

The expansion time in the FIPFG process is the period after the pot life, in which the homogeneously mixed sealant of the particular material system used foams up into a seal.

With the chemical reaction between isocyanate and water in the polyol component, the propellant CO2, essential for foam production, is created as a spin-off product. Through the rise in temperature engendered by the (exothermic) reaction, the CO2 gas foams up the sealant mass.

At the end of the expansion time the propellant has done its job and can escape through the mixed-cell structure of the polyurethane foam.

Liquid gaskets, in-situ sealing foams, cured-in-place - FIPFG (Formed-In-Place-Foam-Gasket)!

Traditionally, components are sealed with pre-punched sponge rubber seals or by bonding sealing cords. Today, as the degree of automation increases, liquid or thixotropic sealing foams are applied directly to the components on site using dosing equipment. There, they cure at room temperature. Also common are the terms in-situ gasket foaming, the application of liquid gaskets to a component in situ, locally foamed gaskets or Cured-In-Place (CIP). The latter highlights the curing of the foam gasket at room temperature.

The FIPFG technology has established itself as the industry standard for a wide variety of component applications. Decisive factors for the FIPFG process are the interaction of material system and machine technology as well as the application-specific understanding of the process.

The FIPFG foam sealing process

Chemical or physical foaming

The chemical reaction of components A (polyol) and B (isocyanate) with water produces CO2, which acts as a blowing agent and foams the material. A mixed-cell soft foam seal is formed.

During physical foaming, under direct air supply into the dosing head mixing chamber, a closed-cell polyurethane foam seal is formed. These SONDERHOFF FIP CC systems can be recognised by the suffix "CC" for "closed cells".

No forming tools are required for either method. Simply by foaming freely on the component surface, the soft foam seal is formed in the desired shape on the surface or in the groove of the component.

An elegant and highly efficient process:

mixing, dosing, foaming.

The foam components A and B are homogeneously mixed in the mixing chamber of the dosing unit in a specified mixing ratio. For this purpose, differently designed agitators are used depending on the formulation and requirement profile.

Immediately afterwards, the liquid or thixotropic 2-component sealing compound is precisely applied directly ("in-place") to the pre-programmed component contour via the CNC-controlled mixing head of the dosing system. The sealing bead, which is precisely deposited on the contour, foams up by more than 3 times its original liquid material volume.

After just a few minutes, a soft, seamlessly closed foam seal is formed at room temperature. In contrast to the inserted sealing cord or sponge rubber seal, there is no seam through which, for example, moisture can penetrate into the industrial part. The coupling point of the seal bead is almost completely invisible.

The FIPFG foam gasket adapts to any workpiece geometry and compensates for dimensional tolerances.

With the right machine, it practically works by itself

Fully automatic, precise, repeatable

Due to the precise, fully automatic control of the dosing system, the foaming process can be reproduced exactly at any time. For this purpose, the linear robot moves the mixing head over the component with a repeat accuracy of +/- 0.1 mm. The control system of the dosing unit coordinates the dosing of the application quantity with the traversing speed of the linear robot.

With the thixotropic (pasty) sealing systems with high viscosity, the stationary foamed sealing can be applied on flat or 3-dimensional surfaces without a groove. Even extreme slopes are possible with FIPFG foam gaskets without material flowing back or to the side.

SONDERHOFF SYSTEM SOLUTIONS: Optimal interaction of material and machine for your production process as well as subcontraction solutions

As a FIPFG expert, we ensure the accuracy of the sealing processes with our SONDERHOFF mixing and dosing systems. In special machine construction, we build the dosing systems optimised to your requirements in order to integrate them into your production concepts in the best possible way.

Different automation solutions for both 2D and 3D components can be implemented. With 3-axis linear robots, a travel range for the mixing and dosing head of up to X/Y/Z 3,000 x 1,000 x 500 millimetres can be achieved. When using 6-axis robots, there are practically no limits, and when using material systems with suitable viscosity, even overhead applications are possible.

Modular design for individual configurations

For gasket foaming according to the FIPFG technology, Henkel offers SONDERHOFF mixing and dosing systems in open and closed design to optimise the space requirement for both larger and smaller components. For mixed-cell foam gaskets, we offer our customers the very successful and proven low-pressure systems. For closed-cell foam sealing, we offer the exclusive world novelty of medium pressure systems.

The dosing systems perform the tasks of material preparation, material application via the mixing head, automation and process control. Liquid, medium and high-viscosity reaction materials made of polyurethane, silicone, epoxy resin can be processed precisely with these systems.

Compression behavior of the seal

Components are permanently sealed by compression of 2-component foam sealing systems based on polyurethane or silicone.

The mixed-cell polyurethane foams achieve optimal tightness with a compression of 30 to 60%, the almost closed-cell silicone foams with a compression of 10 to 30% – depending on the degree of hardness of the foam and according to the specific requirements for tightness.

Depending on the requirements, the components sealed with the foam seal in the overall construction meet the applicable standards and protection classes (IP or NEMA) for protection against dust and water – protection classes up to IP 68 or NEMA 4 and 12 are achieved.

It is just as important for tightness to which extend the foam cell structure is fine-celled. Due to the phenomenon of capillary depression, water is forced out of very small cells to a greater extent than out of the capillaries of a coarse cell structure.

For outdoor use, the polyurethane foam seals offer temperature resistance from -40 to +80 °C. The particularly temperature-resistant silicone foams offer good protection against weather influences such as extreme heat or cold in a range from -60 to +180 °C.

The good resetting ability of the compressed foam seal after it has been de-compressed allows the component to be opened and closed frequently while maintaining a consistently high level of tightness. The resetting ability is generally determined by measuring the so-called compression set (DVR) and tested according to DIN EN ISO 1856.

The DVR describes the permanent residual deformation after compression. The resetting ability of polyurethane foam is > 95% – this means, conversely, that the DVR is < 5%. With silicone foam, the resetting ability is > 97%, the DVR < 3%.

The resetting ability can vary under different conditions (compression, temperature and storage time).

Compression behavior of the PU foam seal on a flat surface

The video shows the polyurethane foam seal FERMAPOR K31 in cross section - first in the uncompressed state, then 50 % compressed, so that the sealing function of the seal is given.

Compression behavior of the PU foam seal in a groove

The video shows the polyurethane foam seal FERMAPOR K31 in a cross section in a groove - first in the uncompressed state, then about 50 % compressed, so that the sealing function of the seal is given and the component is tight.

Compression behavior of the silicone pubic seal on a flat surface

The video shows the silicone foam seal FERMASIL in cross section - first in the uncompressed state, then 30 % compressed, so that the sealing function of the seal is given.

Compression behavior of the silicone pubic seal in a groove

The video shows the silicone foam seal FERMASIL in a cross section in a groove - first in the uncompressed state, then about 30 % compressed, so that the sealing function of the seal is given.

Responding flexibly to individual customer requirements with FIPFG technology

With the FIPFG (Formed-In-Place-Foam-Gasket) technology, we meet the high demands of our customers for sealing quality and contour-accurate tightness of the components.

Our more than 1000 material formulations offer a wide range of properties. Adhesion, temperature stability, elasticity, mechanical load capacity and chemical resistance are the most frequently required properties for foam seals made of polyurethane or silicone.

In this way, components of the most diverse applications can be optimally protected against the penetration of air, gases, dust, moisture and other media.

Strong reasons for the FIPFG sealing technology

- Fully automatic, process-safe, flexible

- Fast, economical and efficient

- Low personnel expenses due to high degree of automation

- Short production cycles and high production speeds

- Reproducible quality of seamless, contour-accurate foam seals

- Nearly invisible self-levelling coupling point

- Free application process – no forming tools required as with 2K injection moulding

- Cost-effective alternative, especially for complex component geometries

- Maximum possible material utilization

- No punching waste as with insert seal

- Maximum flexibility because it can be reprogrammed at any time

- Changes during running production up to complete model changes are possible spontaneously

- Suitable even for smallest series due to free programmability of the dosing system

- Mixed "chaotic" part production with part recognition of the dosing system

- Good integration into existing productions

The saving potential of foamed seals

With the FIPFG (Formed-In-Place-Foam-Gasket) technology, much money can be saved in comparison with the manual insertion of pre-prepared seals. Especially where high production quantities are required and the parts can be provided with a traditional rubber seal only relatively labour-intensively (like EPDM or NBR), the direct foaming of a seal – the automated FIPFG process – offers clear advantages.

With the following example calculation the cost effect can be made clear in principle. Even if it represents a simplified overview, as a first estimate it can also be adapted to other applications.

In the following example an electronics box should be considered, production quantity 2,000,000 items per year, with a sealant length of 30 cm and a sealant thickness of 4 mm.

Calculation of the costs of a traditional manual sealing process

The essential costs are material and labour.

The material costs are calculated from the necessary sealing cord quantity (2,000,000 parts x 30 cm) and the material price (EPDM cord on roll 1,000 m for 300 €). Reckoned per unit, the material costs then runs to 0.09 € for each traditional seal.

The work time per sealing cord is often not exactly known. It is estimated from the number and hours of the necessary employees. In this example, 3 workers work in each of 2 shifts, 8 hours a day, 250 working days a year, to produce 2,000,000 parts – and even then have only 21 seconds’ time to mount a seal. The hourly wage is 20 €. From this arise labour costs of 240,000 € per year, or 0.12 € per part.

Through addition of the material and labour costs we arrive at a total price for manually inserted seals of 0.21 € per seal or 420,000 € per year.

Calculation of the costs for the FIPFG technology

To arrive at the labour costs we have to work out the cycle time for the foaming of a part. The cycle time can be roughly approximated from the estimated robot speed. The maximum robot speed is 58 m/min. As this value, however, is never achieved during application and as certain waiting and rinsing times have to be factored in, we can realistically expect that a part needs on average approx. 7 s to be sealed.

2 shifts x 250 days x 8 h x 3,600 s/h ÷ 7 s/part = approx. 2,000,000 parts

The machine is loaded and unloaded by a single employee per shift. This means labour costs of 0.04 € per part. For additionally incurred costs for energy, water, maintenance, waste disposal and material losses an extra cost of 10% is factored in, i.e. 0.01 €/part.

The sum of the individual seal costs comes to a total per seal of 0.11 €. This means for 2 million parts a year costs of 220,000 €.

| EPDM | FIPFG | |||

|---|---|---|---|---|

| Cost | per seal | Cost p.a. (example) |

per seal | Cost p.a. (example) |

| Material | 0.09 | 180,000 | 0.01 | 20,000 |

| Labour | 0.12 | 240,000 | 0.04 | 160,000 |

| Machine | / | / | 0.05 | 100,000 |

| Other | / | / | 0.01 | 20,000 |

| Total | 0.21 | 420,000 | 0.11 | 300,000 |

| Saving | 0.10 | 120,000 | ||

Summary of the cost comparison

Comparing the costs of the above example calculation clearly shows the savings made possible by FIPFG.

At the same time, it is an idealised comparison. Costs for electricity, pressurised air, water, replacement parts, scrap parts etc. were only applied for the FIPFG technology, and there only with a flat rate of 10 %. In real life, every situation must be considered and compared.

In our experience, however, investment in a machine usually pays itself off after a year’s production of about 50,000 parts, and a cost comparison should be carried out.