Smart mixing and dosing

Experience and precision in every machine component

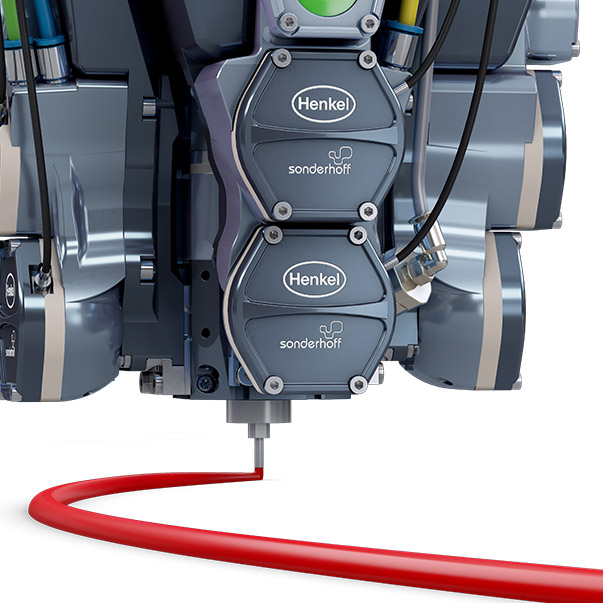

In the mixing head, the components are mixed dynamically and the liquid sealant material system is dosed in precise quantities. All mixing heads are also available with stub lines.

Each of the process steps involved has its own specific requirements, which show how good a machine actually is. Our experience acquired over decades of machine development makes the difference and ensures the reliability of our machines.

Dynamic mixing makes the difference

The greatest possible level of material homogeneity after mixing 2-component material systems with different viscosities – even in the case of demanding, asymmetrical mixing ratios – can only be achieved with dynamic mixing.

The dynamic mixing head enables dosing from 0.2 to 100 g/s with continuously adjustable mixing ratios from 100 : 1 to 1 : 100 and a dosing accuracy of ±1 %. In the case of fast-reacting material, the mixing chamber can also be rinsed regularly – in the case of the MK 800 series with the patented high-pressure water rinsing process!

Better Results – More Efficient Processes

Our “Formed-In-Place” process, or FIP technology for short, i.e. the application of liquid reactive material systems, makes it possible to automate production steps and design processes to suit individual customers. As experts in FIP technology, we achieve the highest accuracy and reproducible quality by combining the processing components of the Sonderhoff equipment portfolio - resulting in highly efficient processes for our customers.

MK 800 / MK 825 PRO mixing heads

Sensor-controlled 2- / 3-component mixing head with high-pressure water rinsing, dynamic mixing and sensor-monitored needle position of the dosing valve

| MK 800 PRO | MK 825 PRO | |||

| Dimensions (H x B x D) 2C mixing head | 272 x 204 x 150 mm | 272 x 204 x 150 mm | ||

| Dimensions (H x B x D) 3C mixing head | 272 x 204 x 202 mm | 272 x 204 x 202 mm | ||

| Operating pressure | up to approx. 20 bar | up to approx. 20 bar | ||

| Discharge rate | 3.0 to 100 g/s | 0.2 to 3.0 g/s | ||

| Dispense accuracy | ±1 % | ±1 % | ||

| Mixing head weight for 2 components | approx. 5.5 kg | approx. 5.5 kg | ||

| Mixing head weight for 3 components | approx. 6.7 kg | approx. 6.7 kg | ||

| Mixing ratio | of 100 : 1 to 1 : 100 continuously adjustable | |||

| Selectable mixer speed | continuously adjustable from 1 – 6,000 rpm | |||

| * Depending on the mixing ratios, material viscosities and the adaptation of pumps, hoses and mixing elements | ||||

Description

-

Sensor-controlled 2-/3-component mixing head with high-pressure water rinsing and dynamic mixing for liquid to highly viscous polymeric reaction materials used for seal foaming, bonding and potting

-

High-pressure water rinsing for ecological cleaning of the mixing system using high-pressure needle valves for rinsing water injection

-

Alternative component rinsing (for the use of non-reactive components)

-

Servopneumatically and hydromechanically controlled precision recirculation valves for precise dosing

-

Can also be equipped with stub lines for bonding or potting applications

-

Weight-reduced construction of a modular design, blue-gray anodized

-

Size-optimized, functional V design to increase the degrees of freedom

-

Robust and maintenance-free design made of high-strength aluminum alloy and chrome steel

-

Direct stack injection of the components

-

Electronically adjustable mixer speed

-

Special mixer design enables gentle material mixing

-

Blowing air needle valve for drying the mixing system

-

Low-drip, low-maintenance nozzle shut-off system STOP-DROP NSS 3

-

Stroke adjustment is automatically adjusted via the control system

-

Sensor-monitored axial position of the agitator shaft

-

Material pressure measurement on the dosing valve

-

Mixing chamber temperature sensor

-

Sensor-monitored needle position of the dosing valve

The New Mixing Heads of the MK 800 Family

Many improvements – one aim: maximum precision

| OPTIONS | IMPROVEMENTS | MK 800 BASIC |

MK 800 Plus | MK 800 Pro |

| Mixing chamber temperature sensor | Unchanged |

|

• |

• |

| Mixing head cooling system by means of a Peltier module (mixing chamber / intermediate housing) |

NEW! Own circuit instead of split circuit Benefit: easier to maintain |

• |

• |

|

| Mixing head temperature control by means of temperature control unit (mixing chamber / intermediate housing) | NEW! Temperature control additionally also for intermediate housing instead of only the mixing chamber Benefit: Higher efficiency |

• |

• |

|

| Manual stroke adjustment by means of adjusting wheel | NEW! Via adjusting wheel instead of with feeler gauge Benefit: Improved adjustability |

• |

• |

|

| Automatic stroke adjustment by means of stepper motor | NEW! Stepper motor Benefit: Fully automatic adjustment |

• |

||

| Sensor-monitored axial position of the agitator shaft | NEW! Detects whether the mixing chamber, agitator and nozzle are installed correctly, Detects signs of wear Benefit: preventive maintenance |

• |

||

| Recirculation valve with manual pressure adjustment / manual pressure regulator | NEW! Manual pressure regulator instead of preloading screw on the valve Benefit: Improved adjustability |

• |

||

| Recirculation valve with automatic pressure adjustment / electronic pressure regulator | Unchanged: Electronic pressure regulator |

• |

• |

|

| Version with stub valve | Unchanged |

• |

• |

• |

| Material pressure measurement directly on the valve | NEW! In the BASIC version (unchanged from PLUS and up) |

• |

• |

• |

| Needle stroke measurement on the dosing and recirculation valve | NEW! Documents I/O functionality of the valve and signs of wear, if applicable Benefit: preventive maintenance |

• |