Control and Monitoring

The sensors installed in the SMART dosing cell and in the MK 800 PRO mixing head determine a wide range of data for seamless monitoring and compliance with critical process parameters such as e.g. temperature, degree of air loading, axial position of the agitator shaft, and the positioning of the needle in the dosing valve.

This provides the machine operator with a comprehensive data-base on the entire application process. It enables fast and precise data analysis for optimized process evaluation and control as well as predictive monitoring of material application processes and preventive maintenance of wear parts.

Control cabinet: The expandable future-proof control center

The control cabinet is the expandable future-proof control center of the SONDERHOFF SMART dosing cell with DM 50x technology. It contains the control components and includes the electrical distribution as well as the control and safety technology and protects them against malfunctions and mechanical damage.

For years the FIPFG sealing technology has been used in control cabinet construction for sealing off against exterior impact. The control cabinets we use are also sealed seamlessly with the polyurethane sealing foams of the FERMAPOR K31 product family in accordance with the DIN EN 61439 standard for switch cabinets, so that neither dust nor moisture can penetrate.

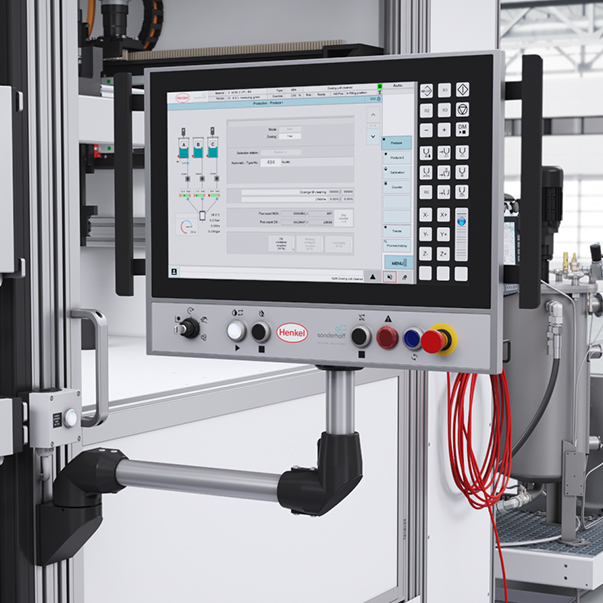

Mobile panel and operating panel as Human Machine Interface (HMI)

In the standard version, the SMART dosing cell is operated via the multifunctional MP 2 Mobile Panel with 10.1 inch touch screen. It is portable, which makes it easier to program the part contours. The 21.5-inch CONTROL 2 multi-touch operating panel is offered as an option.

The graphical user interfaces provide continuous information on the performance status of the system and the process data collected by the installed sensors. A user-friendly menu layout with central navigation enables intuitive menu

navigation.