Fully automatic

The art of process integration

With fully automatic foam sealing, gluing and potting we keep an eye on the customer's entire production process.

The special competence of the Henkel experts for the Sonderhoff technology portfolio lies in thinking about the connection between material, machine and automation - and thus using the potential of the perfect interaction for the optimal integration of the dispensing cell into the customer's production process. Questions of parts handling and how the connection to other upstream and downstream work processes is implemented also play a role here.

Different configurations for feeding and removing parts are available for the SMART-L and SMART-M dosing cell, such as the use of a changing and sliding table, a rotary indexing table or transfer belts. On request, carousels, paternosters or similar can also be integrated into the production process upstream or downstream.

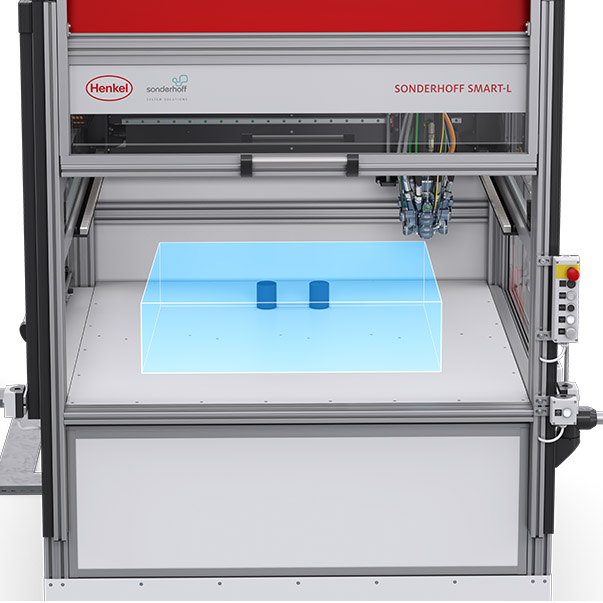

SONDERHOFF SMART L/M dosing cell with different travel ranges

The two SONDERHOFF SMART-L and SMART-M dosing cells differ in their dimensions and, as a result, also in their travel range.

The different options for automating the SMART dosing cells

SONDERHOFF SMART-L/M dosing cells with lifting door

In the standard version, the dosing cells are SONDERHOFF SMART-L/-M equipped with a lifting door on the front. The components for applying sealing foams, adhesives or potting compounds are manually inserted into the dosing cell. The lifting door forms the separation between the robot work area and the employee and thus enables CE conformity.

SONDERHOFF SMART-M dosing cell with rotary indexing table

The component assembly of the SONDERHOFF SMART-M dosing cell for sealing foams, gluing or potting can also be done user-friendly via a rotary indexing table. This has e.g. a 180° division for the loading and working position (other divisions possible). The insertion area is protected by a light grid for component assembly.

SONDERHOFF SMART-L dosing cells with shuttle/sliding table

The component assembly of the SONDERHOFF SMART-L dosing cell can also be done in a user-friendly manner via a changing/sliding table. With this solution, the machine operator loads the two mounting plates alternately with the components.

The aluminum mounting plates are prepared with a drilling pattern for fastening the workpieces or, if required, with workpiece holders. For the dosing job, the receiving plates move alternately in continuous pendulum operation on one level into the working area of the cell.

SONDERHOFF SMART-L dosing cell with conveyor belt system

In the case of the SONDERHOFF SMART-L dosing cell with conveyor belt, optionally equipped with a lifting door on the front, the components are fed in for the dosing job via a conveyor belt running through the cell (single or multi-lane). The circulating conveyor belt, as in this configuration, is also used for clocking out and as the first curing section.