At the Filtech trade fair this year, Henkel and Sonderhoff will be jointly presenting their product and service portfolio for filter manufacturing, tailored to the complex requirements of filter technology. These system solutions meet the high quality requirements that are demanded by filter systems which are often exposed to heavy loads caused by heat, pressure and chemicals.

Customized solutions for the filter industry

Customized solutions provided by a single source can cover the entire value-added chain in filter manufacturer: From technical application consulting and expert training to metalworking, industrial cleaning and surface pre-treatment, right through to bonding and sealing the filters. Henkel and Sonderhoff support a wide range of filter applications. These include filters for the filtration of water, food and beverages as well as for vacuum cleaners, filters in the automotive, medical, oil and gas sector and air filters for ventilation systems.

Lower cleaning costs and higher production outputs

Manufacturers of liquid filtration systems using hollow-fiber membranes in the water, food and beverage industries face the challenge of having to continually raise the reliability and efficiency of their products. In addition, in view of the increasing global scarcity of water, the consumption of water and the cleaning and maintenance costs when cleaning filtration systems must be kept as low as possible. Henkel has developed a two-component epoxy adhesive, Loctite EA 9452, which has proven to be very successful in meeting these high requirements in a practical way. Alongside gaining approval to EU Food Approval 10/2011, EC No. 1935/2004 and the KTW (plastic/drinking water) guidelines, this adhesive is characterized by very good acid and alkali resistance when filtering liquid substrates at pH2 to pH12. It adheres very well to the wet fibers of the filters used in the production process. Above all, the product has a high temperature stability of up to 85°C. "This is a very important feature for cleaning filtration systems. This allows the intervals between the cleaning cycles to be extended, reducing costs and raising production output,” says Frank Lenz, Business Development Manager Filtration for Europe at Henkel, explaining the efficiency benefits.

Foamed filter adhesive saves cost and weight

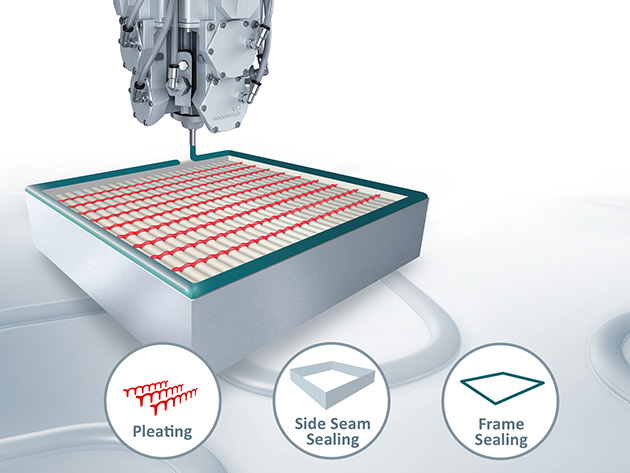

Sealing specialist Sonderhoff, a manufacturer of two-component foam gaskets, adhesives and potting compounds as well as mixing and dosing systems, will be presenting the advantages of their foamed filter adhesive in the Fermadur range. This adhesive sealant bonds the folded filter pack to the interior of the filter frame and is applied using a SMART-M dosing cell. It is a fully automatic unit that provides positional accuracy and reliability. Thanks to the foamed cell structure and the resulting lower density, this product achieves high efficiencies in filter production. The lower weight is an essential criterion for a simpler parts handling. "The amount of adhesive per filter can be reduced by up to 50% thanks to the foamed cell structure. This saves both money and weight, while continuing to meet the requirements for high-quality filter bonding,“ says Dominique Tosi, Head of Application Technology at Sonderhoff, explaining the cost and weight benefits for filter manufacturers.

Excellent fungal and bacterial resistance for adhesives and sealants in air conditioning systems

Efficient adhesives are indispensable for the manufacture of industrial filters. They are used for the stabilization and final bonding of folded filter media. Here Henkel offers the solvent-/BHT-free hot melt adhesive Technomelt AS 5115, which is based on ethyl vinyl acetate. The product is approved to VDI 6022 for use in ventilation and air conditioning systems and is also used for the bonding of clean room filters. Technomelt AS 5115 can be used up to 100°C, impressing with its excellent fungal and bacterial resistance that meets ISO 846. This reduces the effort required for cleaning and disinfecting the filter elements and apparatus. Furthermore, the hot melt adhesive melts and sets quickly and has only limited shrinkage after cooling.

Bonding of filters without the pulling of strings increases process speeds

At temperatures below 140 °C, adhesives tend to pull strings that cause the filter elements to become dirty and machine parts must be cleaned at relatively short intervals. This leads to extended process and throughput times, which in turn leads to increased process costs. In the hot melt adhesive Technomelt AS 5115, Henkel has developed a solution that no longer pulls strings when bonding filters. The process speed can be increased significantly. In this way, Technomelt AS 5115 strikes the manufacturing efficiency demanded by filter producers whilst meeting the quality requirements at the same time.

The joint booth operated by Henkel and Sonderhoff at Filtech is located in Hall 11.2, L1. Here, Henkel and Sonderhoff experts will be providing information on a broad spectrum of efficient solutions for the filter industry.

Further information can be found at www.henkel-adhesives.com.

Individual solutions for filter manufacturing from a single source

For the first time, Henkel and Sonderhoff are presenting their filter manufacturing products on a joint stand at FILTECH 2019. Henkel offers the world's widest range of adhesives and sealants as well as products for surface treatment. Sonderhoff, which has been part of Henkel AG & Co. KGaA since 2017, is a system provider for materials, machines and contract manufacturing. This means that users can benefit from highly effective customized solutions for the entire filter production system from a single source. The result is an improvement in solutions that raise efficiency in filter manufacturing as well as uprating the functions and quality of the filters themselves.