Customized sealing foams

for maximum packaging safety of plastic drum lids

FERMAPOR K31-A-6505-1-N-FD / K31- B-28-FD polyurethane foam with FDA compliance, in accordance with Title 21 of the U.S. Code of Federal Regulation (21 CFR § 174.5), is used to provide a seamless final lid seal for plastic food drums with a capacity of two liters or more.

This polyurethane foam gasket is suitable for use in direct contact with aqueous, acidic, alcoholic, fatty and dry raw food products. This also applies to cold or hot filled or pasteurized milk as well as dairy products. Here, the correct ratio between the contact area of the gasket surface and the filling volume must be maintained.

The FDA-compliant foam gasket is characterized by the excellent migration behavior of the gasket materials used in the formula. The expert opinions of independent testing institutes certify that the values determined for overall migration of the gasket materials are below the limit value of EU Regulation No. 10/2011 of 10 mg/dm². The smell and taste, as well as the appearance and consistency of the food filled in plastic drums, do not change.

Frequent opening and closing of the drums with a constant sealing effect

The foam gasket in the groove of the lid is compressed when the drums are closed and almost completely recovers when they are reopened.

If the barrel is closed again the excellent foam resetting ability ensures that the sealing properties and low water absorption of the lid gasket are maintained over the long term while providing optimum adhesion to plastic.

Material systems for drum lids made of plastic

The tear strength and elongation at break of the FDA-compliant foam gasket have been improved through consistent development of the mechanical properties. Even in the event of drops, impacts and vibrations, the lids of the plastic drums sealed with foam gaskets suitable for foodstuffs remain leak-proof.

Our reference material FERMAPOR K31-A-9843-8-VP2 / K31-B-5 is used for sealing the lids of plastic drums for industrial products such as paints, varnishes, construction materials and aggregates.

We can also adapt our sealing foams to meet your specific technical requirements. Sonderhoff sealing foams can be customized, for example, in terms of reactivity, hardness, viscosity, color and other chemical and physical properties.

The different reaction phases of the sealing foam in the chronological sequence

Reference material

|

Plastic drums for |

Plastic drums for food products | |||

| FERMAPOR K31 | A-9843-8-VP2 | A-6505-1-N-FD | ||

| B-5 | B-28-FD | |||

|

Mixing ratio |

4.5 : 1 | 3.05 : 1 | ||

|

Pot life |

46 Sek. | 35 Sek. | ||

|

Tack-free time |

9 Min. | 8 Min. | ||

|

Viscosity of the A component |

9,000 mPas | 6,200 mPas | ||

|

Density |

0.29 g/cm³ | 0.28 g/cm³ | ||

|

Hardness (Shore 00) |

67 | 80 | ||

|

Temperature resistance |

von -40 bis + 80 °C | von -40 bis + 80 °C | ||

|

Pretreatment (optional) |

Plasma, Corona, Flamme oder Primer | Plasma, Corona, Flamme oder Primer |

In addition to the reference products, we develop material systems according to your individual requirements. The influencing factors include the pot life until the start of foam formation, the curing time as well as the viscosity, the hardness and the adhesion properties.

Compression behavior

Cross-section of a polyurethane foam bead in groove uncompressed

Cross-section of a polyurethane foam bead in the groove and compressed to approx. 50 %

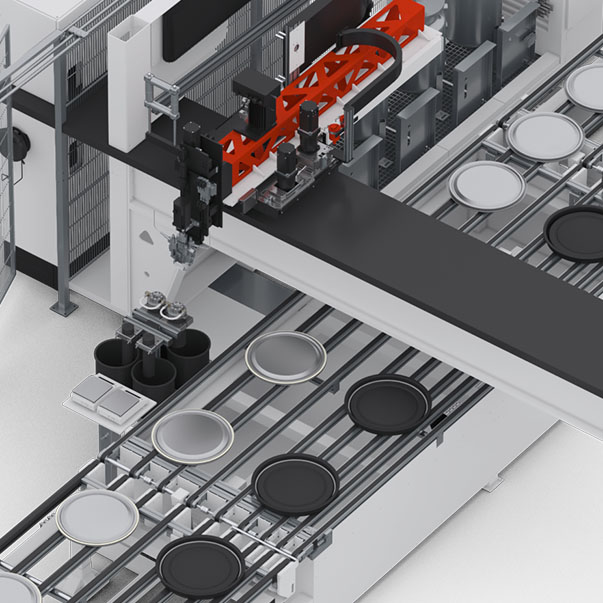

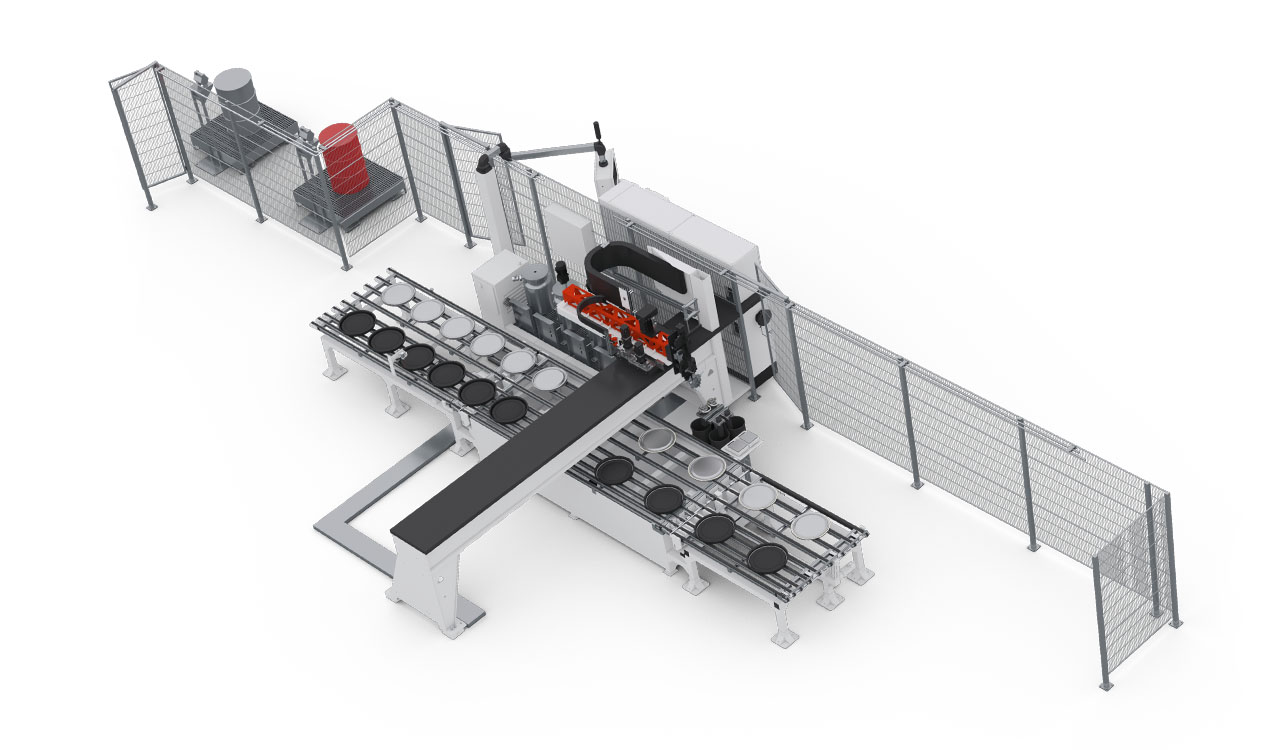

Mixing and dosing system DM 502 with 3-axis linear robot and conveyor belt for feeding parts

Flexible and fully automatic –

according to your requirements

As a process expert, we offer economical and efficient solutions for the customized automation and integration of our mixing and dosing systems into your production processes.

The reference configuration shown here is used for the fully automatic and contour-accurate application of 2-component sealing foams into the groove of the lids of metal or plastic drums. It consists of the DM 502 mixing and dosing system with a 3-axis linear robot and a conveyor belt system for feeding parts and clocking out.

The drum lids are fed to the dosing station at the cycle rate specified for your production, where they pass under the 3-axis linear robot. At the centering station, the lid is positioned on the belt in such a way that the mixing head controlled by the linear robot can move along the lid groove with contour accuracy and apply the precisely dosed discharge quantity into the groove.

Alternatively, the sealing foam can also be dispensed into the groove by rotating the lid. The discharge quantity is fed into the groove of the lid via the mixing head in relation to the rotational speed.

With the high volumes and short cycle times of drum lid production, our dosing machines with FIPFG technology enable the efficient and precise application of material. The highly dynamic LR-HD or, alternatively, the highly efficient LR-HE plus 3-axis linear robot ensures precise contour guidance of the MK 825 PRO precision mixing head over the contour of the lid.

Both application variants apply the sealing foam into the lid groove with high dosing and repetition accuracy. The coupling point of the foam gasket closes seamlessly and is therefore almost invisible. After expanding by several times the specified material volume, a soft foam gasket with the desired foam hardness is produced and cures at room temperature.

Elevator

Supply Tap

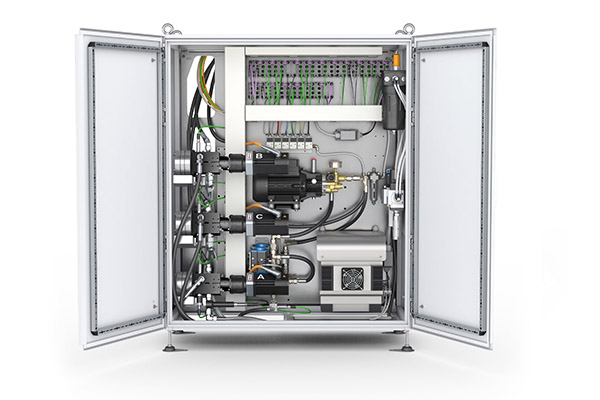

Material pressure tanks

CONTROL 2

Dosing machine cabinet

Control cabinet

Mischkopf 825 PRO

MP 2 Mobilpanel

Elevator

Supply Tap

Material pressure tanks

CONTROL 2

Dosing machine cabinet

Control cabinet

Mischkopf 825 PRO

MP 2 Mobilpanel

Elevator

Optional: Automatic ELEVATOR drum refilling station for the A-component with pneumatic lift and agitator

More information to our refilling stationsSupply Tap

Optional: Automatic SUPPLY TAP drum refilling station for low-viscosity products, e.g. isocyanate (B-component)

More information to our refilling stationsMaterial pressure tanks

Material pressure tanks (24 l or 44 l, single-walled or double-walled) with minimum level sensors, on a grating platform with adjustable leveling feet and drip tray

More information to our material Pressure TanksCONTROL 2

Optionally available: CONTROL touchscreen operating panel (21.5“) for operating the dosing system

More information to our operating panelsDosing machine cabinet

The dosing machine cabinet contains the components of the dosing periphery, e.g. the dosing pumps.

More information to our dosing machine cabinetsControl cabinet

The control electronics, safety engineering and industrial PC are installed in the control cabinet.

More information to our control cabinetsMischkopf 825 PRO

MK 800 PRO precision mixing head with high-pressure water rinsing or alternative component rinsing system

More information to our mixing headsMP 2 Mobilpanel

The multifunctional MP 2 mobile panel (10.1” WXGA TFT) enables convenient operation of the dosing system.

More information to our operating panels