The MOLD’N SEAL procedure

Combination of injection molding and foam sealing

The MOLD‘N SEAL procedure – the combination of injection molding with mixing and dosing machine in one production cell – has been developed in cooperation with Arburg and Engel, the manufacturers of injection molding machines.

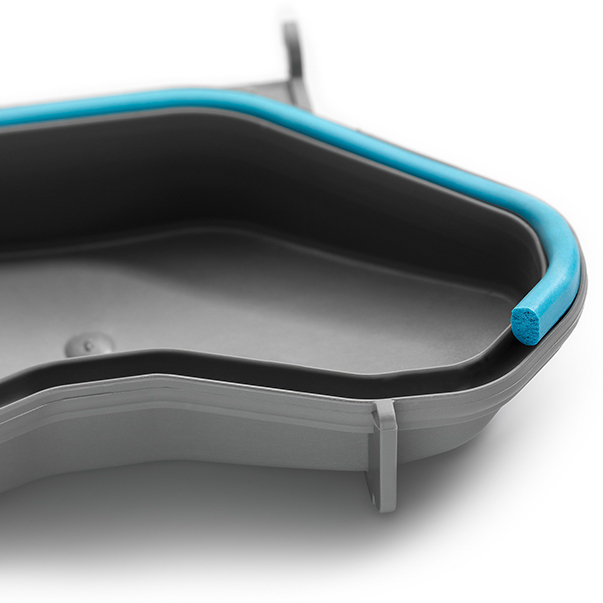

After the injected part is taken out of the molding form, it is directly applied with the FERMAPOR FAST-CURE K31 system, a polyurethane sealing foam especially developed for the MOLD‘N SEAL procedure.

With the MOLD‘N SEAL procedure the two formerly separated processes injection molding and foam gasket application can now be combined in one production step with regard to efficiency and product quality. The injection molding parts no longer need to be prefabricated and stored temporarily as before.

With MOLD'N SEAL the following saving potentials can be realized:

- By a faster curing time of the Fast-Cure seal material (tack-free after 120 sec.) an accelerated further processing is possible.

- Instead of two only one handling robot for the part handling of both processes (injection moulding and foam gasket application) is necessary.

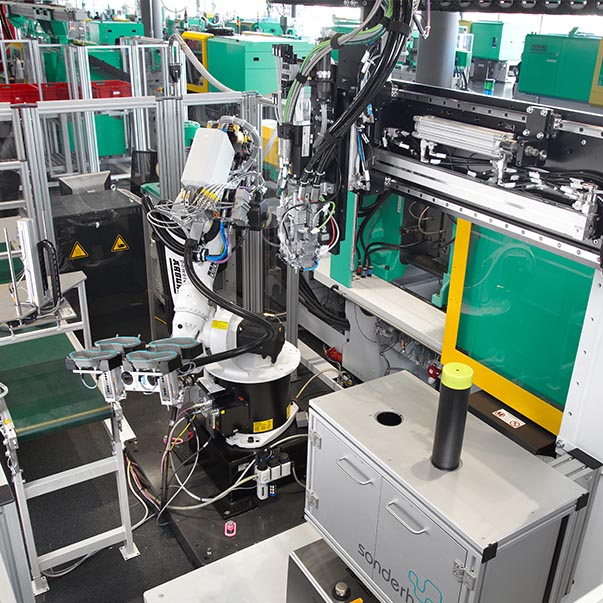

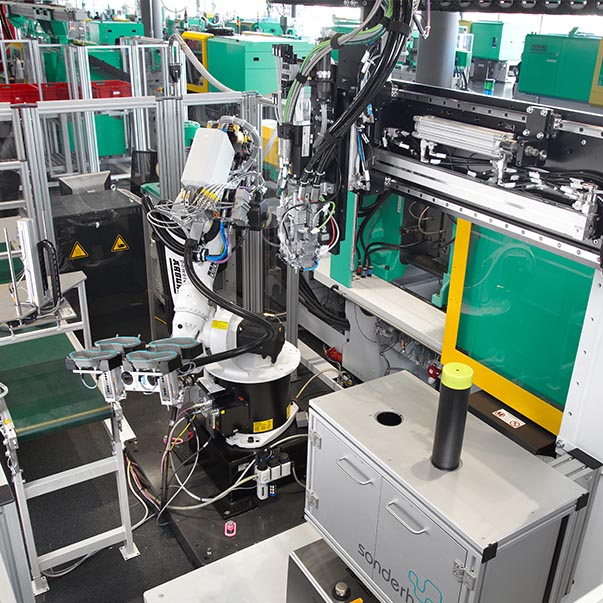

- Through process integration, injection molding machine, six-axis handling robot, mixing and dosing system and discharge conveyor belt need only a very small footprint of just 24 to 40 sq. m. depending on the different format of each configuration.

MOLD'N SEAL process procedure:

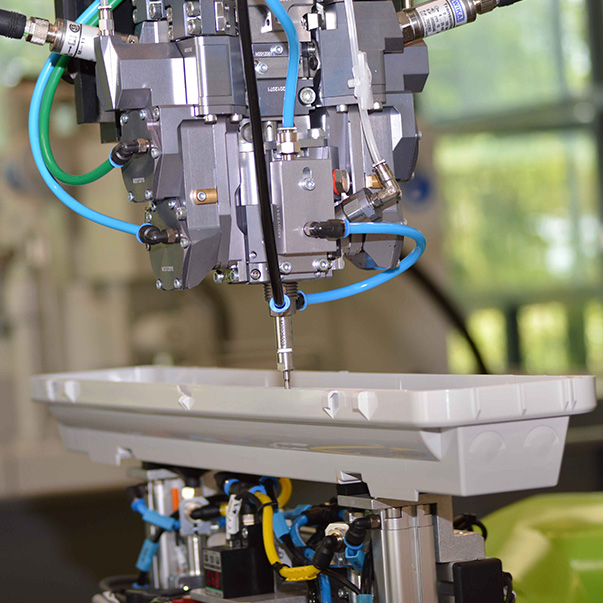

The still warm injection moulded parts are taken out of the mould by a six-axis robot and placed under the mixing head MK 800 of the mixing and dosing machine DM 502/503 which then applies the sealing foam accurate to the contour of the part.

The polyurethane Fast-Cure sealing system from the product family FERMAPOR K31 is cured significantly fast, additionally promoted by the residual warmth of the just injection moulded part.

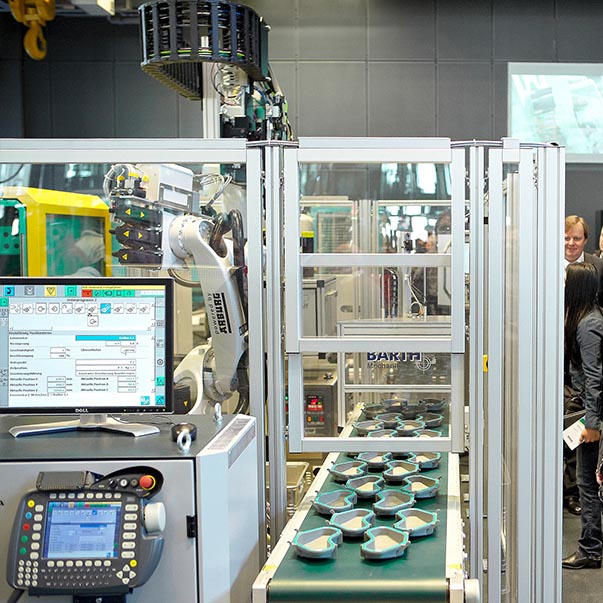

Already shortly after the foam gasket application the handling robot positions the part on the conveyor belt for further processing.

The MOLD'N SEAL process can be adapted to different cycle times of injection molding and to parts with various geometries and mold cavities (one-to-four-fold tools) for direct foam sealing. Additional processes like pre-treatment of the plastic part’s surface by ionisation or plasma treatment can also be integrated.

Movie of Mold'n Seal process with Engel

Movie of Mold'n Seal process with Arburg

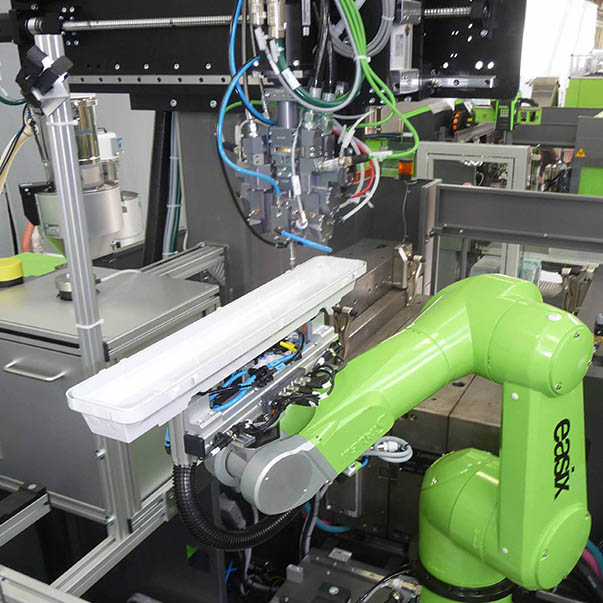

Automation with Engel

With the MOLD‘N SEAL process housings for moisture-proof lamps by Zumtobel Lighting are injected molded on a hydraulic ENGEL machine, the victory 1350/300 tech series, and immediately afterwards applied with a FERMAPOR K31 FAST CURE polyurethane seal foam into the housing groove by the mixing head of the SONDERHOFF dosing machine.

More than 523 lamp housings could be produced in an unbroken eight-hour shift. Within 55 seconds per production cycle the components were injection molded, removed from the mold, foamed and placed on the integrated discharge belt for curing and further processing.

Process details

The housing of the moisture-proof lamp is removed from the injection molded system using the ENGEL easix robot and stored in a holding and cooling position. Then, the robotic arm takes a cooled part, guides it past the ionisation station to the MK 800 mixing head of the DM 502 mixing and dosing system and positions the housing groove directly under the mixing head dosing nozzle.

The 6-axis robot is programmed in such a way that it scans the part contour two times, whereby the dosing nozzle of the MK 800 applies the polyurethane sealant precisely inside on the basis of the groove which is just a few millimetres wide.

The discharge performance is just 0.45 g/s per application cycle of total two material layers dosed into the groove. After placing them on the discharge conveyor belt, the injection molded part cools down and the foam sealant is tack-free within two to three minutes. This makes it possible to further process the part after a brief period of time.

Material

The rapid-reaction 2-component Fast-Cure seal foam from the FERMAPOR K31 product family, which was specially developed for the MOLD‘N SEAL procedure, can bridge a mixing head waiting period of 25 seconds.

In this time, the robotic arm picks up a new injection molded part from the tool, places it in the cooling position, and removes a part that was already there, guides it past the ionisation station and begins the seal foam application afresh with its position under the mixing head.

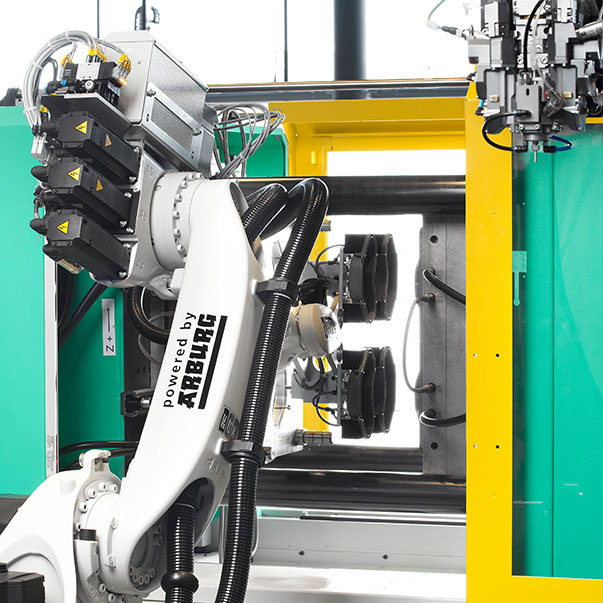

Automation with Arburg

With the MOLD‘N SEAL process more than 2,500 back cap parts were injection moulded on a hydraulic injection moulding machine from Arburg, type Allrounder 570 S with 2.200 kN closure force and a 4-fold tool, during an eight hours shift.

Directly afterwards the polyurethane based Fast-Cure foam sealing from the product line FERMAPOR K31 was applied in the groove of the parts.

Process details

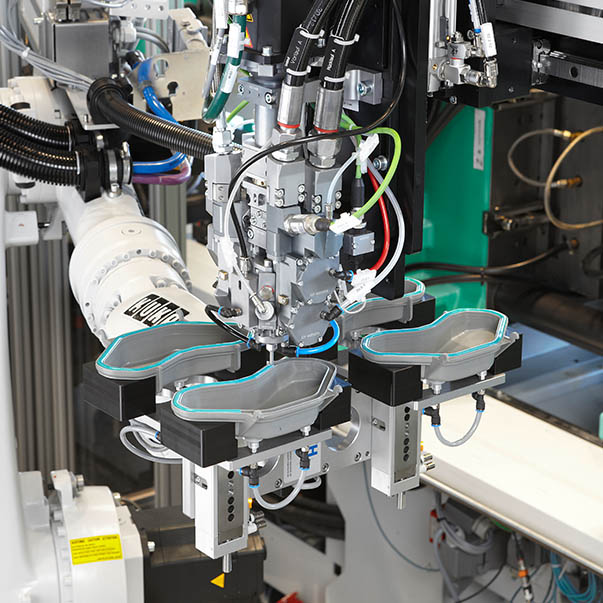

The process in detail: Within a cycle time of 45 seconds, four parts are injection molded, taken out of the four-fold mold with a 6-axis handling robot. Immediately afterwards the FERMAPOR K31 FAST-CURE polyurethane seal foam, specially developed for the MOLD'N SEAL process, is applied with the MK 800 mixing head of the DM 502 dosing system. Then the four parts are placed on the conveyor belt integrated in the production cell for curing and further processing.

The 6-axis robot is programmed in such a way that the mixing head MK 800 is moved accurate to the part contour so that the dosing nozzle can place the foam gasket material into the groove. The discharge performance is 1.17 g/s. The handling robot hands over the parts to the transfer station of the production cell which places them on the discharge belt. The foam gasket becomes tack-free within 2 to 3 minutes and can be further processed after short time.

Material

The rapid-reaction 2-component Fast-Cure seal foam from the FERMAPOR K31 product family is adapted to the injection molded cycle that it can bridge a mixing head waiting period of 18 seconds. During this time, the robotic arm picks up new back cap parts from the injection mold tool, holds them under the mixing head, scans the contour of each of the four parts and applies the foam gasket into the part groove.

After handing them over to the transfer station the back cap parts are positioned on the assembly line for curing and further processing, and the foam sealing application process starts again.