Reliable mixing and dosing

Experience and precision in every machine component

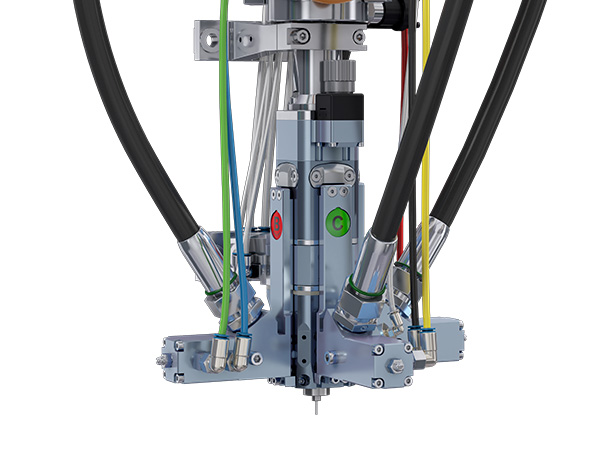

A mixing head for processing two or three components has three essential functions. Firstly, the precise dosing of two components into the mixing chamber at the specified mixing ratio through the built-in valve technology. Secondly, the components are homogeneously mixed within the mixing chamber by the servo-controlled agitator. Then the material is applied precisely onto the part through the dosing nozzle.

For material systems with simple mixing ratios and generous processing tolerances, static mixing is often enough. Here, the two material components only need to be pressed through a mixing tube in the correct quantity ratio. The material flow is then swirled by the inside structures of the mixing tube to such an extent that sufficient mixing occurs.

Dynamic mixing makes the difference

The greatest possible level of material homogeneity after mixing 2-component material systems with different viscosities – even in the case of demanding, asymmetrical mixing ratios – can only be achieved with dynamic mixing. Static mixers are capable of swirling material components of similar viscosity during continuous dosing. These can be used for material systems that allow generous deviations in the mixing ratio and react comparatively slowly, thereby preventing material that has already stuck together in the mixing tube from collecting and forming a blockage.

The dynamic mixing head is totally different. For example, it enables dosing from 0.2 to 100 g/s with continuously adjustable mixing ratios from 100 : 1 to 1 : 100 and a dosing accuracy of ±1%. In the case of fast-reacting material, the mixing chamber can also be rinsed regularly – in the case of the MK 800 series with the patented high-pressure water rinsing process!

MK 800 PRO with extended mixing chamber

For components that are not easily accessible due to their design and require sealing, bonding or potting in places, it may be necessary to extend the discharge nozzle. However, this is only possible to a limited extent, as it would otherwise lead to back pressure.

We have therefore designed a solution that makes it possible to fit inaccessible components with a seal, for example. The mixing chamber was extended, as was the stirrer installed in it over its full length, and fitted with a short discharge nozzle.

With this solution, it is possible to bridge up to 60 cm (depending on material viscosity and process conditions).

Animation of the MK 800 mixing heads

MK 800 BASIC / PLUS / PRO

Sonderhoff MK 800 with the patented high-pressure water rinsing process

The New MK 800 Mixing Head Series

Many improvements – one aim: maximum precision

| OPTIONS | IMPROVEMENTS | MK 800 BASIC |

MK 800 Plus | MK 800 Pro |

| Mixing chamber temperature sensor | Unchanged |

|

• |

• |

| Mixing head cooling system by means of a Peltier module (mixing chamber / intermediate housing) |

NEW! Own circuit instead of split circuit Benefit: easier to maintain |

• |

• |

|

| Mixing head temperature control by means of temperature control unit (mixing chamber / intermediate housing) | NEW! Temperature control additionally also for intermediate housing instead of only the mixing chamber Benefit: Higher efficiency |

• |

• |

|

| Manual stroke adjustment by means of adjusting wheel | NEW! Via adjusting wheel instead of with feeler gauge Benefit: Improved adjustability |

• |

• |

|

| Automatic stroke adjustment by means of stepper motor | NEW! Stepper motor Benefit: Fully automatic adjustment |

• |

||

| Sensor-monitored axial position of the agitator shaft | NEW! Detects whether the mixing chamber, agitator and nozzle are installed correctly, Detects signs of wear Benefit: preventive maintenance |

• |

||

| Recirculation valve with manual pressure adjustment / manual pressure regulator | NEW! Manual pressure regulator instead of preloading screw on the valve Benefit: Improved adjustability |

• |

||

| Recirculation valve with automatic pressure adjustment / electronic pressure regulator | Unchanged: Electronic pressure regulator |

• |

• |

|

| Version with stub valve | Unchanged |

• |

• |

• |

| Material pressure measurement directly on the valve | NEW! In the BASIC version (unchanged from PLUS and up) |

• |

• |

• |

| Needle stroke measurement on the dosing and recirculation valve | NEW! Documents I/O functionality of the valve and signs of wear, if applicable Benefit: preventive maintenance |

• |

• Standard features

• Optional features

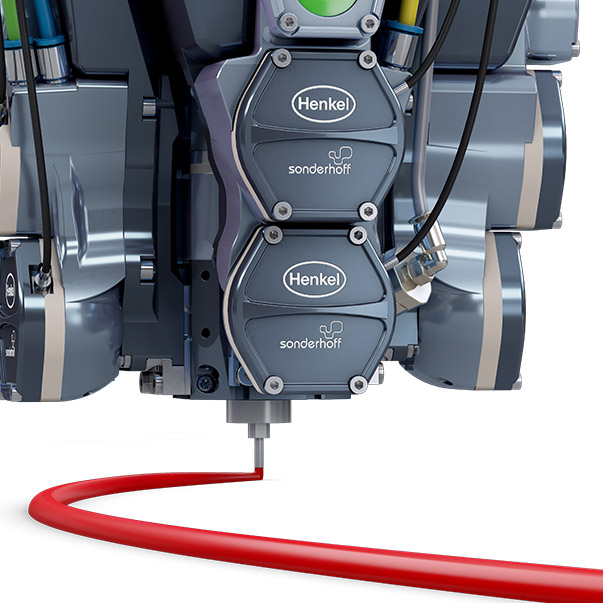

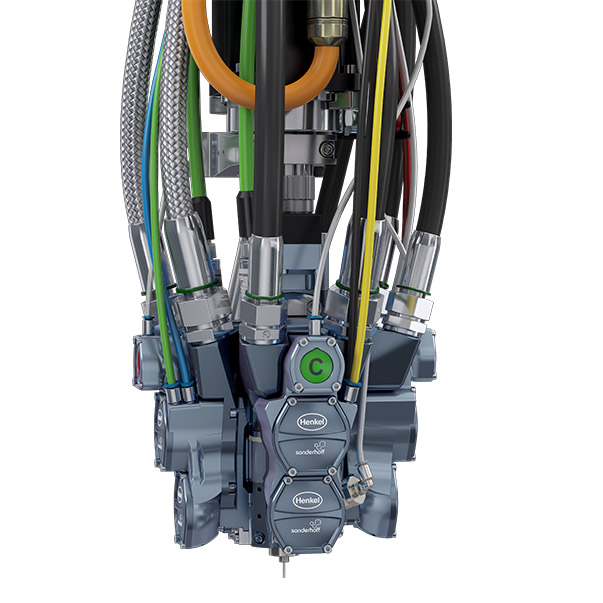

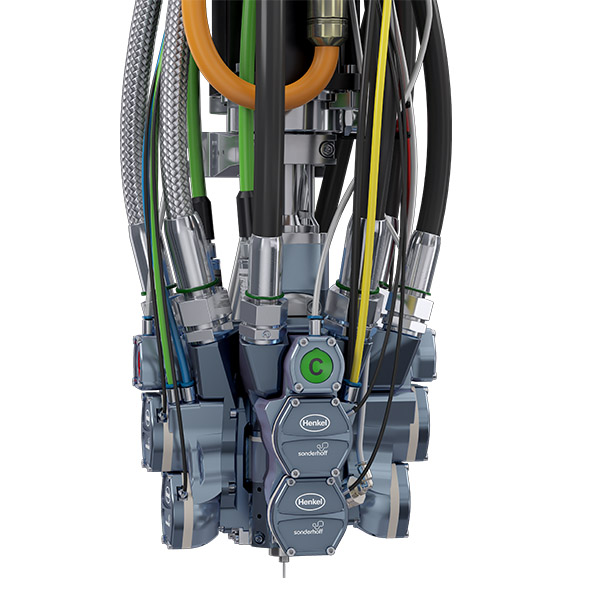

MK 800 / MK 825 BASIC mixing heads

2- / 3-component-mixing head with high-pressure water rinsing and dynamic mixing

Animation of Sonderhoff MK 800 BASIC

| MK 800 BASIC | MK 825 BASIC | |

|---|---|---|

| Dimensions (H x B x D) 2C mixing head | 248 x 237 x 151 mm | 248 x 237 x 151 mm |

| Dimensions (H x B x D) 3C mixing head | 248 x 237 x 219 mm | 248 x 237 x 219 mm |

| Operating pressure | up to approx. 20 bar | up to approx. 20 bar |

| Discharge rate | 3.0 g/s to 100 g/s | 0.2 g/s to 3.0 g/s |

| Dispense accuracy | ± 1 % | ± 1 % |

| Mixing head weight for 2 components | approx. 5.5 kg | approx. 5.5 kg |

| Mixing head weight for 3 components | approx. 6.7 kg | approx. 6.7 kg |

| Mixing ratio | of 100 : 1 to 1 : 100 continuously adjustable | |

| Selectable mixer speed | from 1 – 6 ,000 U/min | |

| * Depending on the mixing ratios, material viscosities and the adaptation of pumps, hoses and mixing elements | ||

DESCRIPTION

-

2- / 3-component mixing head with high-pressure water rinsing and dynamic mixing of liquid to highly viscous polymeric reactive materials for seal foaming, bonding and potting

-

High-pressure water rinsing for ecological cleaning of the mixing system

-

Alternative: rinsing with A-component

-

Hydromechanically regulated precision valves for precise dosing

-

Can also be equipped with stub lines for bonding or potting applications

-

Weight-reduced construction of a modular design, blue-gray anodized

-

Robust and maintenance-free design made of high-strength aluminum alloy and chrome steel

-

Direct multi-level injection of components

-

Electronically adjustable stirrer speed

-

Special stirrer design enables gentle material mixing

-

Blowing air needle valve for drying the mixing system

-

Low-drip, low-maintenance nozzle shut-off system STOP-DROP DVS 3

-

DVS 3 stroke can be easily adjusted by means of an adjusting wheel

-

Material pressure measurement on the dosing valve

Options

- Mixing head housing made of chrome steel

- Customer-specific outlet nozzles

- Spraying system

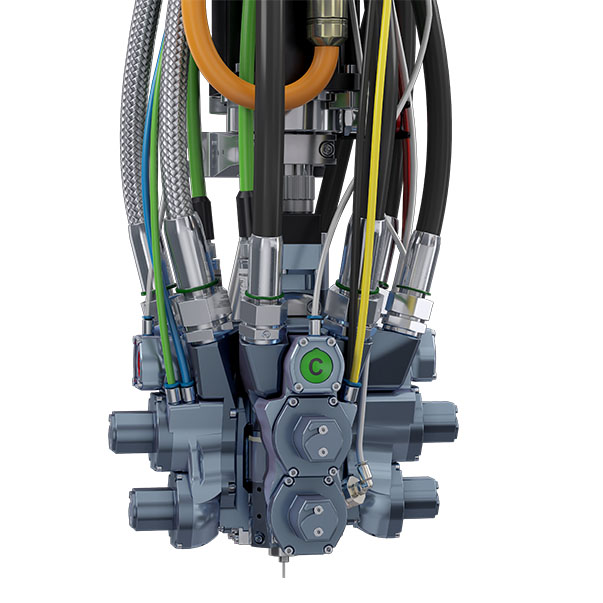

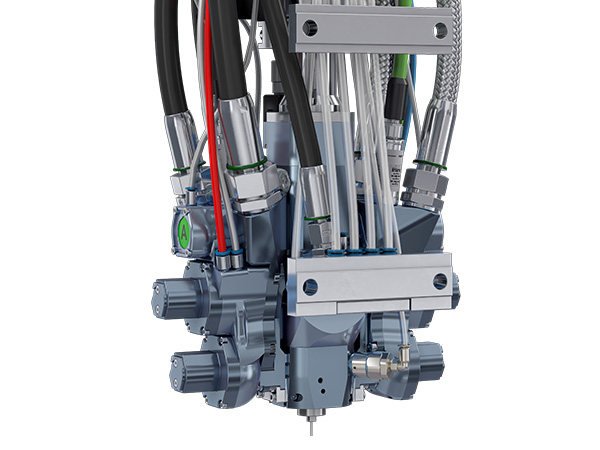

Rear view of mounting bracket and valve cluster

Adjusting wheel for stroke adjustment of the nozzle shut-off system DVS 3

Optionally also available in a version with stub valves

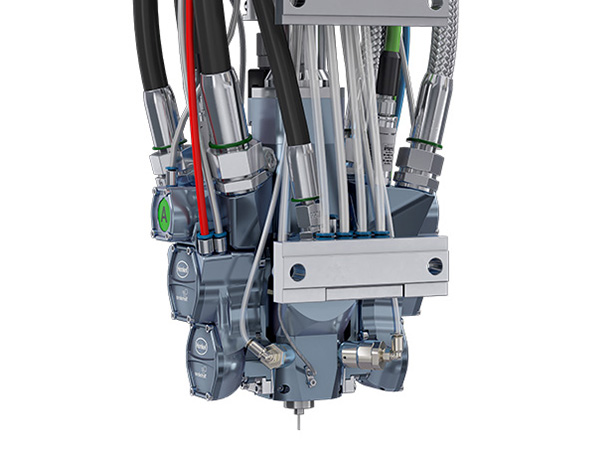

MK 800 / MK 825 PLUS mixing heads

Sensor-controlled 2- / 3-component mixing head with high-pressure water rinsing, dynamic mixing and mixing chamber temperature sensor

Animation of Sonderhoff MK 800 PLUS

| MK 800 PLUS | MK 825 PLUS | ||

|---|---|---|---|

| Dimensions (H x B x D) 2C mixing head | 248 x 204 x 151 mm | 248 x 204 x 151 mm | |

| Dimensions (H x B x D) 3C mixing head | 248 x 204 x 202 mm | 248 x 204 x 202 mm | |

| Operating pressure | up to approx. 20 bar | up to approx. 20 bar | |

| Discharge rate | 3.0 g/s to 100 g/s | 0.2 g/s to 3.0 g/s | |

| Dispense accuracy | ± 1 % | ± 1 % | |

| Mixing head weight for 2 components | approx. 5.5 kg | approx. 5.5 kg | |

| Mixing head weight for 3 components | approx. 6.7 kg | approx. 6.7 kg | |

| Mixing ratio | of 100 : 1 to 1 : 100 continuously adjustable | ||

| Selectable mixer speed | continuously adjustable from 1 – 6,000 rpm | ||

| * Depending on the mixing ratios, material viscosities and the adaptation of pumps, hoses and mixing elements. | |||

Description

- Sensor-controlled 2- / 3-component mixing head with high-pressure water rinsing and dynamic mixing of liquid to highly viscous polymeric reactive materials for seal foaming, bonding and potting processes

- High-pressure water rinsing for ecological cleaning of the mixing system

- Alternative: rinsing with A-component

- Servopneumatically and hydromechanically controlled precision valves for precise dosing

- Can also be equipped with stub lines for bonding or potting applications

- Weight-reduced construction of a modular design, blue-gray anodized

- Size-optimized, functional V-shaped design to increase the degrees of freedom

- Robust and maintenance-free design made of high-strength aluminum alloy and chrome steel

- Direct multi-level injection of components

- Electronically adjustable stirrer speed

- Special stirrer design enables gentle material mixing

- Blowing air needle valve for drying the mixing system

- Low-drip, low-maintenance nozzle shut-off system STOP-DROP DVS 3

- DVS 3 stroke can be easily adjusted by means of an adjusting wheel

- Material pressure measurement on the dosing valve

- Mixing chamber temperature sensor

Options

- Mixing head housing made of chrome steel

- Customer-specific outlet nozzles

- Spraying system

- Mixing head temperature control

Rear view of mounting bracket and valve cluster

Adjusting wheel for stroke adjustment of the nozzle shut-off system DVS 3

Optionally also available in a version with stub valves

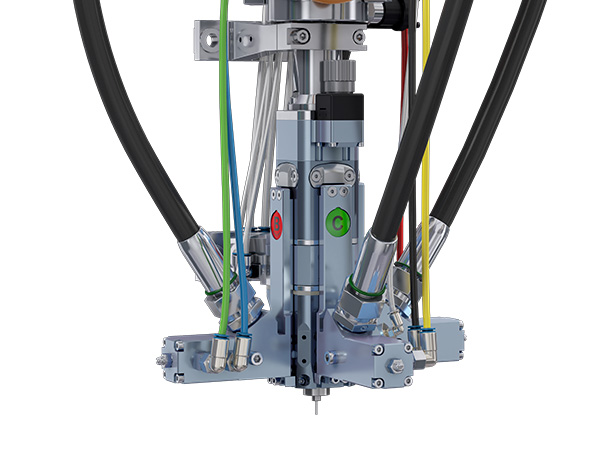

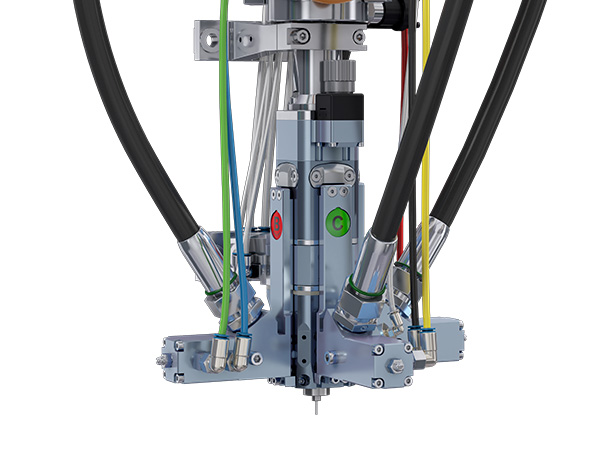

MK 800 / MK 825 PRO mixing heads

Sensor-controlled 2- / 3-component mixing head with high-pressure water rinsing, dynamic mixing and sensor-monitored needle position of the dosing valve

Animation of Sonderhoff MK 800 PRO

| MK 800 PRO | MK 825 PRO | |||

| Dimensions (H x B x D) 2C mixing head | 272 x 204 x 150 mm | 272 x 204 x 150 mm | ||

| Dimensions (H x B x D) 3C mixing head | 272 x 204 x 202 mm | 272 x 204 x 202 mm | ||

| Operating pressure | up to approx. 20 bar | up to approx. 20 bar | ||

| Discharge rate | 3.0 to 100 g/s | 0.2 to 3.0 g/s | ||

| Dispense accuracy | ±1 % | ±1 % | ||

| Mixing head weight for 2 components | approx. 5.5 kg | approx. 5.5 kg | ||

| Mixing head weight for 3 components | approx. 6.7 kg | approx. 6.7 kg | ||

| Mixing ratio | of 100 : 1 to 1 : 100 continuously adjustable | |||

| Selectable mixer speed | continuously adjustable from 1 – 6,000 rpm | |||

| * Depending on the mixing ratios, material viscosities and the adaptation of pumps, hoses and mixing elements | ||||

Description

- Sensor-controlled 2- / 3-component mixing head with high-pressure water rinsing and dynamic mixing of liquid to highly viscous polymeric reactive materials for seal foaming, bonding and potting processes

- High-pressure water rinsing for ecological cleaning of the mixing system

- Alternative: rinsing with A-component

- Servopneumatically and hydromechanically controlled precision valves for precise dosing

- Can also be equipped with stub lines for bonding or potting applications

- Weight-reduced construction of a modular design, blue-gray anodized

- Size-optimized, functional V-shaped design to increase the degrees of freedom

- Robust and maintenance-free design made of high-strength aluminum alloy and chrome steel

- Direct multi-level injection of components

- Electronically adjustable stirrer speed

- Special stirrer design enables gentle material mixing

- Blowing air needle valve for drying the mixing system

- Low-drip, low-maintenance nozzle shut-off system STOP-DROP DVS 3

- DVS 3 stroke adjustment is automatically carried out via the control system

- Sensor-monitored axial position of the agitator shaft

- Sensor-monitored needle position of the dosing valve

- Material pressure measurement on the dosing valve

- Mixing chamber temperature sensor

Options

- Mixing head housing made of chrome steel

- Customer-specific outlet nozzles

- Spraying system

- Mixing head temperature control

Stepper motor for automatic adjustment of the nozzle shut-off system DVS 3

Optionally also available in a version with stub valves