Material Pressure Tank

Different Animation to our material pressure tanks

Animation of material pressure tanks

Material evacuation with thin layer process:

Thermal sleeve for material pressure tanks

Material air loading with the thin layer process

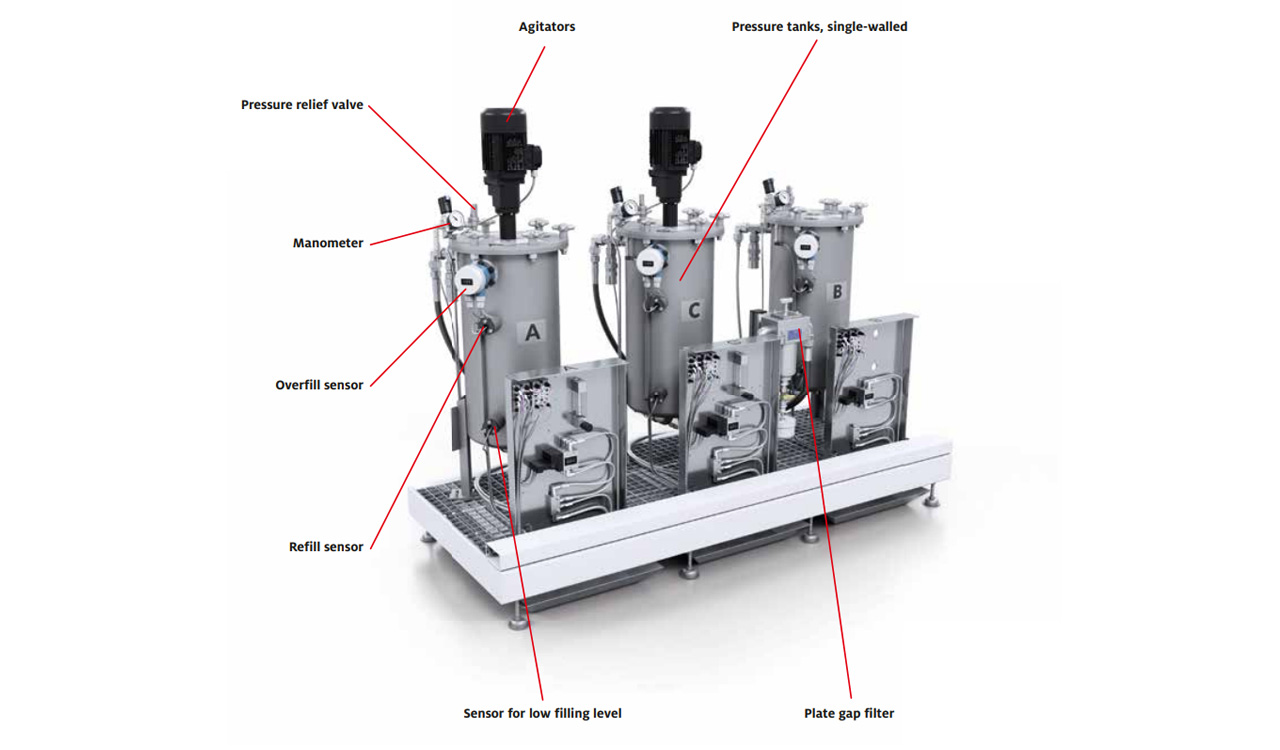

DESCRIPTION

- Material pressure tank with capacitive minimum fill-level sensors, safety pressure valve (TÜV type-tested), overfill protection (only in conjunction with the use of a refilling station) and shut-off ball valve, with compressed air fittings and compressed air reducing valves for pre-pressure regulation of the tank pressures

- Material pressure tank, single-walled, galvanized steel with 24 l or 44 l capacity

- Material pressure tank, single-walled, chrome-nickel steel with 24 l or 44 l capacity

- Material pressure tank, double-walled, chrome-nickel steel with 24 l, 44 l or 90 l capacity

- Wire mesh filter cartridges and plate gap filters

- Three-phase agitator turning at 22 rpm, or alternatively at 99 rpm

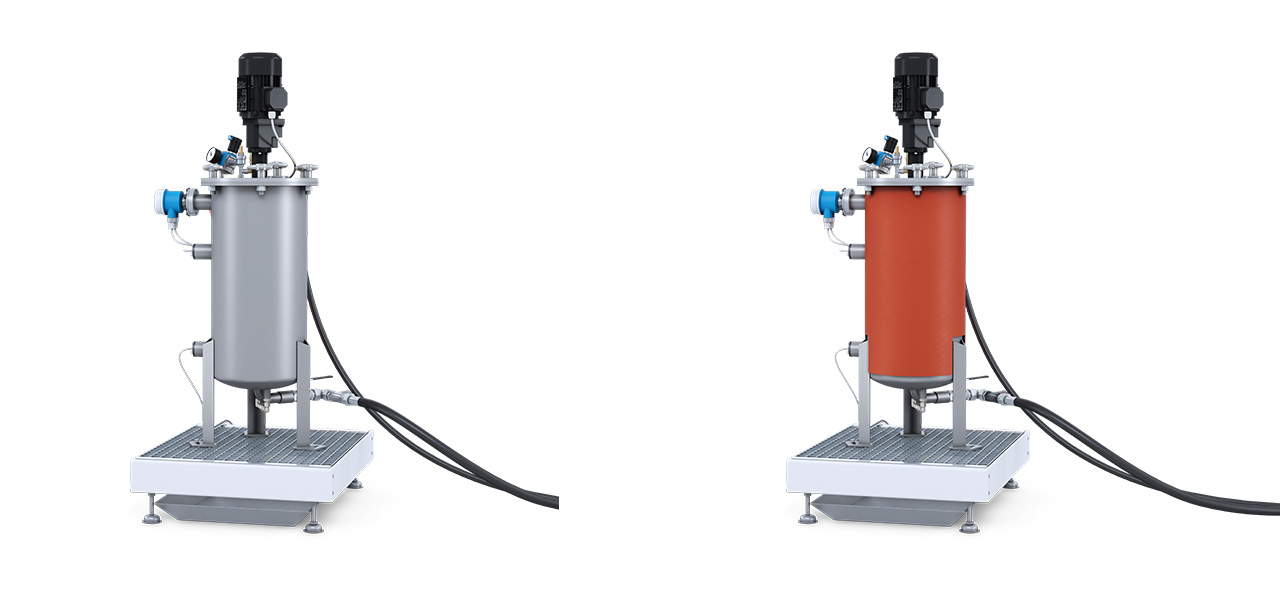

- Electric heating for single-walled containers

- Temperature control for double-walled containers

- Automatic air loading

- Manual evacuation

- Preparation for the control of an automatic refilling device

- Material supply through refilling stations for containers from 20 to 1,000 liters

- Recirculation hose package

- Electric heated hoses with steel-reinforced Teflon high-pressure hose core

- Double-walled medium heating hose with Teflon high-pressure hose core

- Container platform: Galvanized grating, with adjustable leveling feet and drip tray, standing separately

- Platform incl. material pressure tank (per component): B x H x D 625 x 1,500 x 860 mm, approx. 85 kg

Double-walled material pressure tank Double-walled material pressure tank

in cross-section with view of air with temperature control unit

loading and agitator for heating and cooling the material

Single-walled material pressure tank Single-walled material pressure tank

without heating jacket with heating jacket