Self-adhesive polyurethane foam gasket

for universal use

Are you looking for a quick and easy way to seal your components? With the self-adhesive polyurethane foam gaskets, we offer an efficient and practical solution for a wide range of applications for industrial components – from switch cabinet engineering to various applications in the automotive industry and air-conditioning technology.

As a "ready-to-use" solution, our self-adhesive polyurethane foam gasket helps in various situations: during component production or for the quick repair of a component seal directly on site.

The self-adhesive polyurethane foam gasket is available as standard in two different heights (5 mm and 8 mm) on a roll with a length of 50 meters, from which you can conveniently cut off the desired seal length, thus reducing waste to a minimum. We can also supply you with self-adhesive foam gaskets prefabricated as seamless seals, in any dimension you require.

The double-sided transparent self-adhesive strip of the foam gasket provides a strong adhesive and mechanically resilient adhesive base for almost all materials. It adheres reliably to almost all surfaces, from powder coatings to LSE (low surface energy) surfaces.

As a result, self-adhesive polyurethane foam gaskets offer a flexible and cost-effective alternative whenever the use of a fully automatically applied FIPFG gasket is not practical or possible.

Standard height approx. 5mm and approx. 8mm -

The resulting width-height ratio is approx. 2 : 1

Roll with self-adhesive polyurethane foam gasket

(length: approx. 50 meters)

Self-adhesive polyurethane foam gasket for different applications

Manually place in a radius

The self-adhesive foam gasket is cut from the roll in the desired seal length.

By peeling off the cover paper, it is placed in the radius and attached to the surface of the component contour that is to be sealed.

Gasket in prefabricated form

The self-adhesive foam gasket is also available in a prefabricated form in your desired dimensions.

CNC-controlled material application makes the gasket seamless with an almost invisible coupling point.

Miter cutting

The user can miter cut the self-adhesive foam gasket for component corners and radii.

The cut edges are butted in the corner and can be additionally bonded.

Customize with a miter cut

The user can miter cut the self-adhesive foam gasket for component corners so that it is not completely cut through.

The cut edges are folded towards each other and the gasket is glued onto the component. The cut surfaces can also be additionally bonded.

Self-adhesive polyurethane foam gasket

for universal use

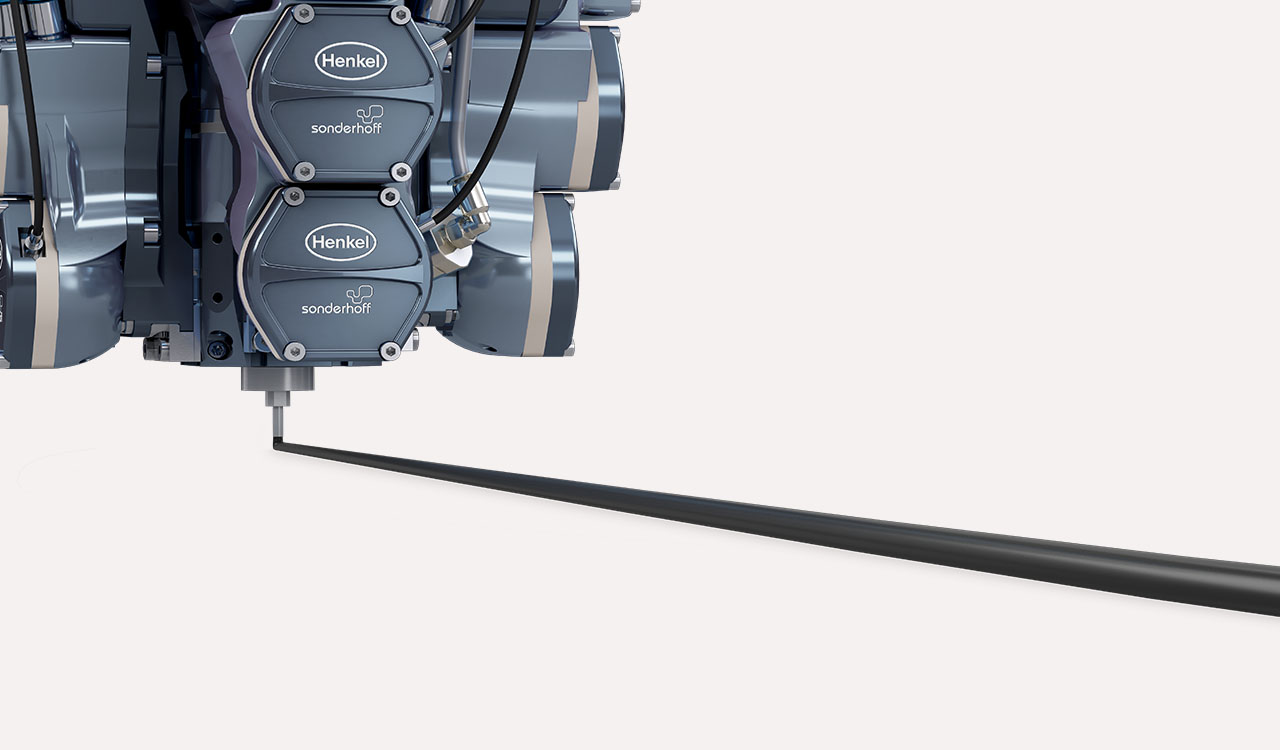

The self-adhesive foam gasket is made from our recommended reference material, the 2-component polyurethane foam FERMAPOR K31-A-4555-2-AD / K31-B-4, using the Formed-In- Place-Foam-Gasket (FIPFG) technology.

The foam consists of a base resin (A component) and a hardener (B component), which are homogeneously mixed with each other in the mixing head of the dosing machine in a predetermined mixing ratio.

Afterwards, the dosing application is carried out fully automatically and precisely to the contour of the self-adhesive strip with our mixing and dosing machine. The double-sided transparent self-adhesive strip of the foam gasket provides a strong adhesive and mechanically resilient adhesive base for almost all materials. It adheres reliably to powder coatings as well as to LSE (Low-Surface-Energy) surfaces.

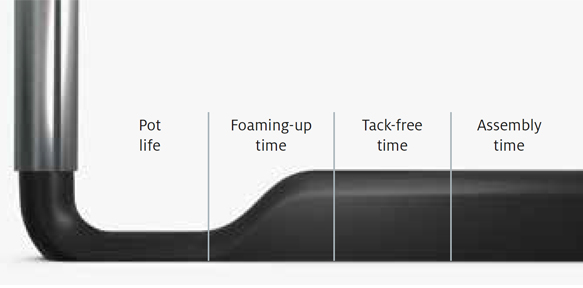

When foaming, the material applied on the self-adhesive strip forms a compressible, uniform foam gasket. After the reaction is complete, approx. 50 meters of the self-adhesive foam gasket are prepared on rolls.

Even after years of continuous use, the foam gasket has an almost 100 % resetting ability in its foam structure, so that there is always sufficient foam thickness for the compression of the foam gasket and therefore a consistently high sealing effect. This is particularly important for all components that have to be opened and closed for maintenance purposes.

Referenzmaterial

| FERMAPOR K31-A-4555-2-AD | |||

| FERMAPOR K31-B-4 | |||

|

Mixing ratio |

4.5 : 1 | ||

|

Density |

0.21 g/cm³ | ||

|

Hardness (Shore 00) |

39 | ||

|

Temperature resistance |

from -40 to + 80 °C | ||

|

UL certification |

UL 50E |

Transparent self-adhesive tape

|

Total thickness |

205 μm |

Temperature resistance |

|

|

Material adhesion |

long-term |

100 °C | |

|

Stahl |

11,80 N/cm |

short-term |

200 °C |

|

ABS |

12,00 N/cm |

Elongation at break |

50 % |

|

Aluminium |

10,60 N/cm |

Ultimate tensile strength |

20 N/cm |

|

PC |

14,00 N/cm |

Resistance to aging |

sehr gut |

|

PE |

6,90 N/cm |

Moisture resistance |

sehr gut |

|

PET |

9,50 N/cm |

Chemical resistance |

gut |

|

PP |

7,90 N/cm |

Resistance to softener |

gut |

|

PS |

12,00 N/cm |

UL Standard 969 / UL File |

MH 18055 |

|

PVC |

13,00 N/cm |

|

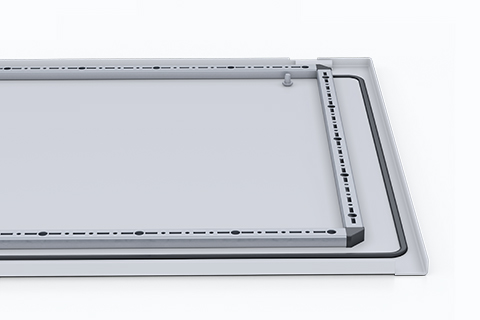

Self-adhesive polyurethane foam gasket in enclosures

The switch cabinet, consisting of a rear panel, side panels and doors, is sealed throughout its entire structure to protect the electronics installed in the cabinet.

The self-adhesive polyurethane foam gasket can be used for this purpose or if damaged parts of the gasket contour need to be repaired.

Stainless steel switch cabinet door

Switch cabinet door with powder coatings

Self-adhesive polyurethane foam gasket in HVAC units

HVAC unit with external cladding consisting of powder-coated panels sealed with PU foam.

Self-adhesive polyurethane foam gasket on powder-coated HVAC cladding panel

Self-adhesive polyurethane foam gasket with double-sided transparent strip