MP 2 multi-functional mobile panel

The SONDERHOFF 3E SIL dosing cell is designed to enable the operator to perform a wide variety of tasks easily and safely. The system is operated via the easy-to-use, multi-functional Sonderhoff MP 2 mobile panel with integrated 10.1“ touchscreen. This makes the contour programming of components significantly simpler.

The MP 2 mobile panel continuously provides information on the performance status of the system and the process data recorded. This ensures traceability of the preceding production process at all times. In addition, the sensor system installed in the dosing machine continuously supplies measurement data on the factors influencing the production process, which can be prognostically evaluated and proactively readjusted.

Features:

-

MP 2 multi-functional mobile panel with integrated touchscreen (10,1“ WXGA TFT)

-

Intuitive operation with programmable keys, function keys and touch keys

-

Display language options for DE, EN, ESP, IT, F & CHIN, further languages upon request

-

Modular IPC control system in the switch cabinet with Powerlink

-

Selection for Setup / Stand-by / Manual / Automatic operating mode

-

Recipe management

-

Operator password protection selectable on 4 levels

-

Programmable pot life monitoring and dosing quantity preselection, as well as automatic rinsing and material conditioning (air loading, stirring, etc.)

-

Automatic and spontaneously available flow rate adjustment through pressure regulation

-

Preparation of automatic refilling

-

Component pressure monitoring, digital component pressure display

Visualization of the user interfaces

Intuitive system operation and simple evaluation of machine parameters

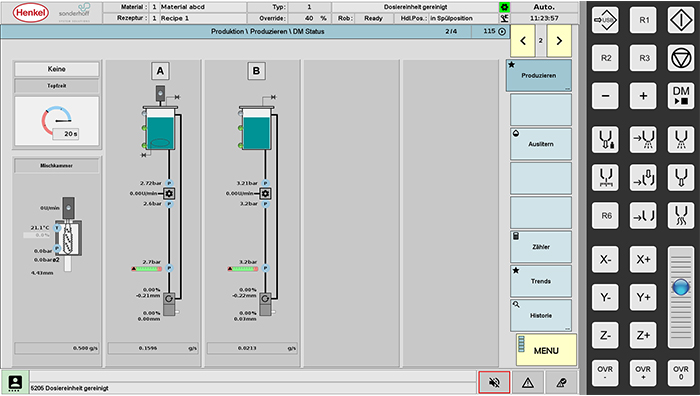

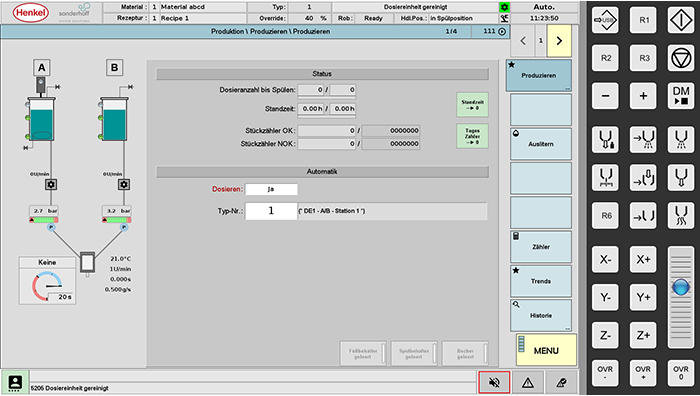

The user interface of the MP 2 mobile panel provides continuous information on the performance status of the dosing cell and the process status of the processing according to the predefined dosing program. Due to the high level of detail of the display, the machine operator can always take corrective action and adjust the process parameters of the system if necessary. The use of universally comprehensible symbols on the operating keys simplifies operation. Clear menu layouts, the use of colored graphics, and the clear structuring of different functions in the operating menu enable intuitive operation and programming of the dosing system.

Overview of the menu structure:

First Column: Reactivity of the material (pot life in seconds) for active material components, plus detailed information on the mixing chamber and agitator

Columns 2–3: Overview of the two material components, display of the filling level in the pressure tank, line pressure upstream of the pump, speed of pump, line pressure downstream of the pump, component pressure at the valve, recirculation control value in %, recirculation valve offset in mm, recirculation status, dosing control value in %, dosing valve offset in mm, current component dosing rate (g/s)

Shows the two material components, the tank level, the pump speed, the line pressure downstream of the pump, the mixing head temperature, the dispensing time (seconds), the discharge line (g/s) and the reactivity of the material (pot life in seconds)