Automatic refilling stations for the 3E PUR, SIL and FLEX

The 3E dosing cell can optionally be equipped with a refilling station for automatic material supply. This ensures material-specific preparation, homogeneous consistency and a continuous supply of materials to the material pressure tanks of the mixing and dosing system – without exposure to or contamination of the products to be filled. The BIG ELEVATOR and ELEVATOR refilling stations have an automatic lifting device for improved ease of operation and greater operational and system safety. Production interruptions are therefore a thing of the past.

The stations are controlled via the mixing and dosing system. Capacitive sensors monitor the filling level in the material pressure tanks.

A choice of unregulated and regulated agitators with adjustable speed ranges and a programmable timer are available to ensure optimal homogenization of the reaction materials. For the ELEVATOR and BIG ELEVATOR refilling stations, the agitator can be equipped with different agitating elements depending on the material.

Existing production plants can be retrofitted.

Equipment Features:

-

Column with drum lid lift, or alternatively with pump holder (ELEVATOR models)

-

The drum lid lifting device is moved pneumatically (ELEVATOR models)

-

Optional material conditioning by means of an electric geared agitator with agitator shaft and agitator blade

-

Agitator programming with clock timer built into the switch cabinet of the refilling station

-

Pneumatic piston pumps or diaphragm pumps, adaptable

-

Hose package for connection to the mixing and dosing system

-

Drip tray with grating (option)

-

Pump and hose set for larger application capacities (optional)

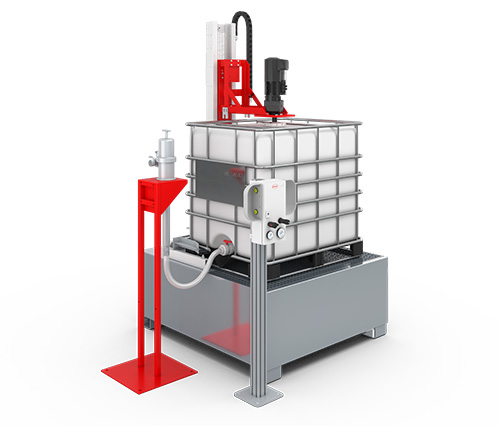

BIG ELEVATOR

Automatic container refilling station with lifting device and optional regulated or unregulated agitator for liquid and thixotropic products (e.g. polyols)

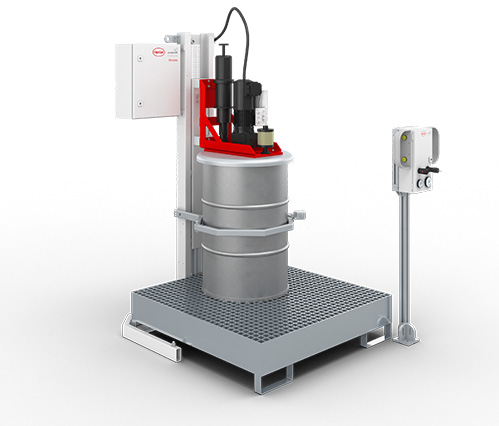

ELEVATOR

Automatic barrel refilling station with lifting device and optional regulated or unregulated agitator for liquid and thixotropic products (e.g. polyols)

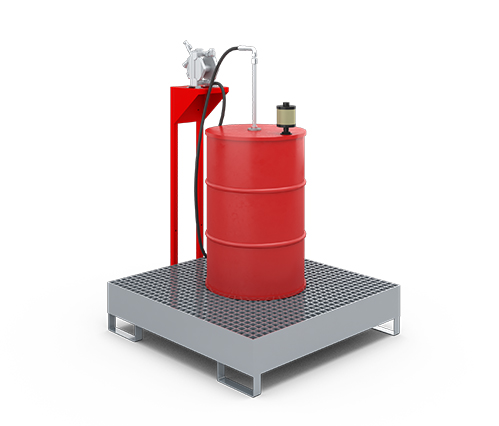

SUPPLY TAP

Automatic drum refilling station for low-viscosity products (e.g. isocyanates)

| Paint coating | 2K textured paint RAL 7035 (light grey) / RAL 3020 (red) |

|---|---|

| Piston pump ratio | From 5 : 1 to 10 : 1 and from 10 : 1 to 55 : 1 |

| Agitator speed |

With the unregulated version: 23 rpm at 0.18 kW With the regulated version: 20 - 150 rpm at 1.5 kW; |

| BIG ELEVATOR | Automatic container refilling station with agitator (0.18 kW), unregulated, without pump; Automatic container refilling station with agitator (1.5 kW or 3 kW), regulated, without pump |

| ELEVATOR | Automatic drum refilling station with agitator (0.18 kW), unregulated, with piston pump; Automatic drum refilling station with agitator (1.5 or 3 kW), regulated, with piston pump |

| SUPPLY TAP | Automatic drum refilling station with piston or diaphragm pump |