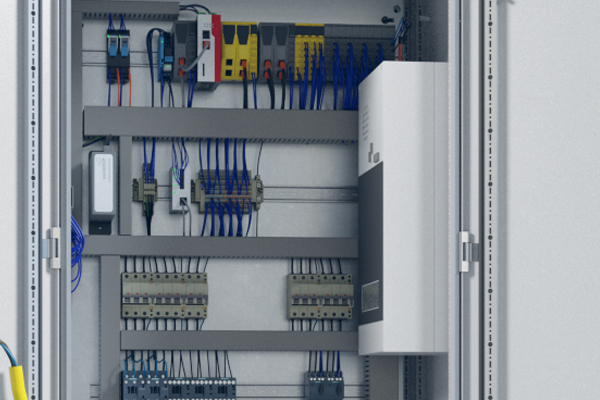

The control cabinet of the 3E PUR dosing cell

The switch cabinet is the expandable future-proof control center of the SONDERHOFF 3E PUR dosing cell with DM 50x technology. It includes the electrical distribution as well as the control and safety technology for the dosing machine and the CNC control of the 3-axis linear robot installed in the cell.

With the programmable safety logic, adjustments to the safety function are now simple and quick to implement. The safety functions of the 3-axis linear robot’s servo axes are fully integrated into the safety logic and can therefore also respond very quickly to safety events. The digital EnDat encoders of the servo motors ensure very precise path behavior of the servo axes when moving the mixing head. The power supply of the servo controllers is provided by a central module, which also handles the communication of the control system.

Control concept:

-

Servo technology with integrated safety logic

-

Safe Limited Speed / Safety Modules

-

Modular B & R branded “IPC control system” with Powerlink

-

VPN router for remote maintenance (remote collaboration)

-

Cooling device for switch cabinet temperature control

-

Clock timer with automatic switch-on

-

EMERGENCY STOP switch-off with a tried-and-tested safety concept, realtime-capable bus system

-

Switch cabinet mounted on the common dosing cell chassis

-

Data backup by means of USB stick or via LAN

-

Data storage for operating system and system programs

-

Safety deactivation on the lifting door

The various components in the control cabinet of the 3E PUR

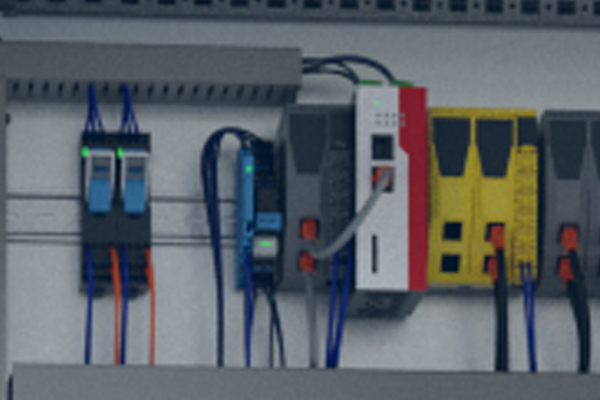

VPN router for remote maintenance (remote collaboration)

Safe Limited Speed / Safety Modules

Modular B & R branded “IPC control system” with Powerlink

Cooling device for switch cabinet temperature control

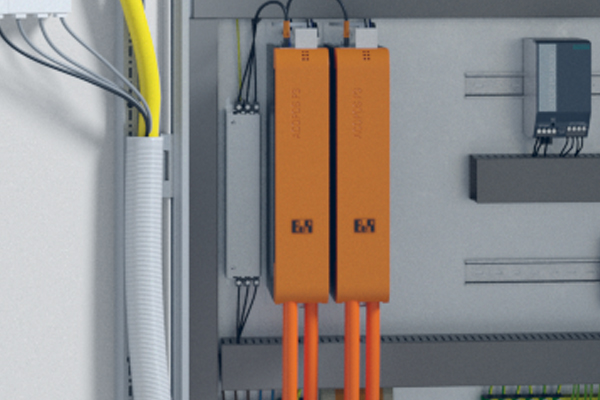

Servo technology with integrated safety logic

VPN router for remote maintenance (remote collaboration)

Safe Limited Speed / Safety Modules

Modular B & R branded “IPC control system” with Powerlink

Cooling device for switch cabinet temperature control

Servo technology with integrated safety logic

VPN router for remote maintenance (remote collaboration)

Safe Limited Speed / Safety Modules

Modular B & R branded “IPC control system” with Powerlink

Cooling device for switch cabinet temperature control

Servo technology with integrated safety logic