Fully automatic

The art of process integration

The way in which the mixing head is moved over the part is fundamental to the construction of the mixing and dispensing system and depends on the way you wish to integrate it into your production process. Sonderhoff offers you many possibilities and even more industry-specific experience. Whether it's semi-automated island solutions or complex inline designs developed together with your automators – we’ve probably done it before!

Maximum precision

Moving the mixing head over the component with a 2- or 3-axis LR-HD or LR-HE linear robot plus mounted on a steel profile framework.

The MKVE 2-axis mixing head traversing unit ensures the precise positioning of the mixing head above the component for the dosing application.

Maximum compactness

Moving of the mixing head with a 3-axis linear robot mounted in a dispensing cell.

Maximum mobility

Moving the mixing head with a 6-axis robot – in this case, upside-down application is possible with the right choice of material.

Maximum productivity

Naturally it is also possible, with 6-axis robots, to pick up the part and move it under a fixed mixing head, in order to address the most complex geometries. The fully automatic MOLD'N SEAL inline production comprises a dispensing system and 6-axis robots combined with an injection moulding system.

Maximum simplicity

It remains always up to you whether you want to move the mixing head by hand – providing you have enough strength. But then, you could still always get a robot to help...

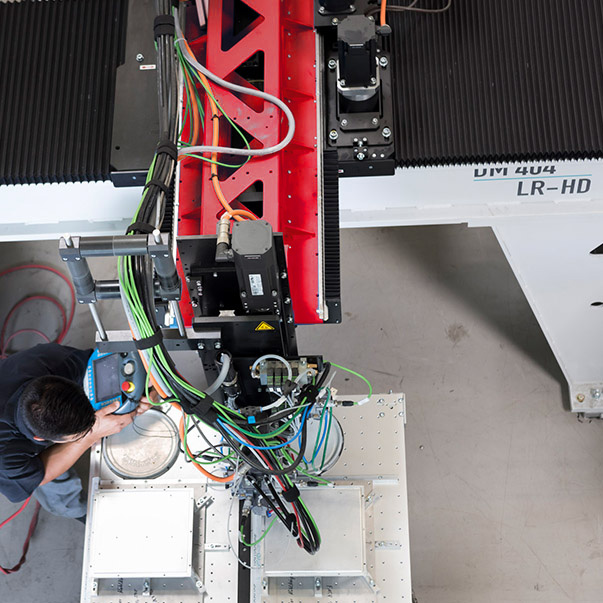

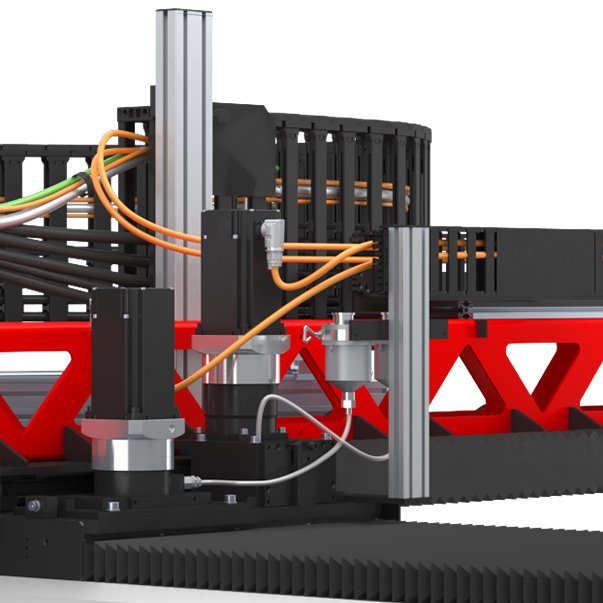

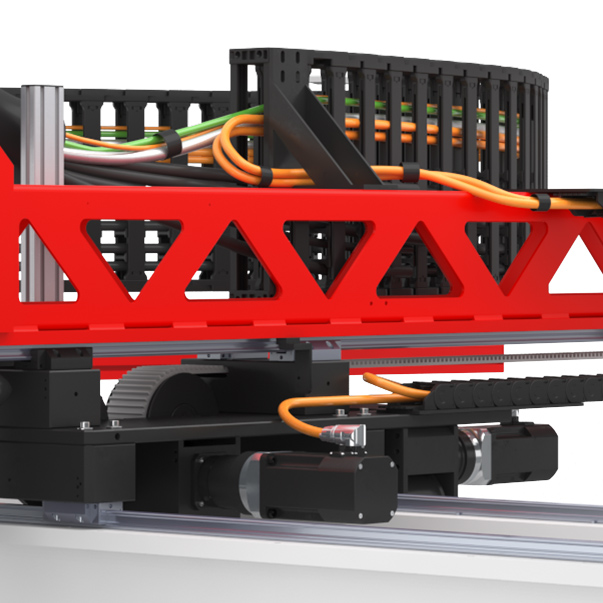

LR-HD

Linear robot „High Dynamic“

Highly dynamic 3-axis linear robot for the precise guidance of mixing heads for the application of polymer reactive materials. The rack and pinion drive with high stiffness and acceleration enables dynamic application speeds in conjunction with abrupt changes in direction and small radii.

DESCRIPTION

High acceleration, tight radii and flowing movements over long contours are no problem for the LR-HE plus and LR-HD linear robots. The dynamic 3-axis linear robots are characterized by high stiffness and acceleration values over a very large travel range. For the highest precision in terms of repeat accuracy, the CNC linear robot with its low level of deviation of ±0.2 mm over a length of 2 m usually has an advantage compared to the 6-axis industrial robot arm. Preferred fields of application are those with high application speeds in conjunction with rapid changes in direction.

- Programming and control by means of dialog input in menu technology with the multifunctional MP 2 Mobile Panel

- Control by means of the IPC control system of the mixing and dosing system

- Base frame made of a stable steel profile beam construction, welded, with screwable foot stand, leveling feet and preparation for floor anchorage

- Guide system with low-wear linear bearings and spindle drive on the Z axis

- Energy guiding chain to accommodate all pneumatic, electric and hydraulic lines

| Max. travel speed | 58 m/min | ||

|---|---|---|---|

| Max. acceleration | 10 m/s2 | ||

| Repetition accuracy | +/- 0.08 mm | ||

| Payload | 20 kg | ||

| Electrics | Design according to EN 60 204-1 | ||

| Base frame painting | 2C textured paint RAL 7035 (light gray) / RAL 3020 (red) | ||

| Input voltage |

3 x 400 V, 50 Hz or 60 Hz or country-specific adaptation |

||

| Rated power | approx. 2 kVA | ||

| Average consumption | approx. 1 kVA | ||

Variants

- 1,000 x 1,000 x 300 mm (X/Y/Z)

- 1,500 x 1,000 x 300 mm (X/Y/Z)

- 2,000 x 1,000 x 300 mm (X/Y/Z)

- 2,500 x 1,000 x 300 mm (X/Y/Z)

- 3,000 x 1,000 x 300 mm (X/Y/Z)

- Optional Y-Axis 1,250 / 1,500 mm

- Optional Z-Axis 500 mm

3-axis linear robot LR-HD rack-and-pinion drive

LR-HE plus

Linear robot „High Efficiency“

Highly efficient 3-axis linear robot for the precise guidance of mixing heads for the application of polymer reactive materials. The Omega toothed-belt drive enables high application speeds for components with medium and large radii.

DESCRIPTION

High acceleration, tight radii and flowing movements over long contours – no problem for the LR-HE plus and LR-HD linear robots. The dynamic 3-axis linear robots are characterized by high stiffness and acceleration values over a very large travel range. For the highest precision in terms of repeat accuracy, the CNC linear robot with its low level of deviation of ±0.2 mm over 2 m usually has an advantage over the 6-axis robot. Preferred fields of application are those with high application speeds in conjunction with rapid changes in direction.

- Programming and control by means of dialog input in menu technology with the multifunctional MP 2 Mobile Panel

- Control by means of the IPC control system of the mixing and dosing system

- Base frame made of a stable steel profile beam construction, welded, with screwable foot stand, leveling feet and preparation for floor anchorage

- Guide system with low-wear linear bearings and spindle drive on the Z axis

- Energy guiding chain to accommodate all pneumatic, electric and hydraulic lines

| Max. travel speed | 35 m/min | ||

|---|---|---|---|

| Max. acceleration | 5 m/s2 | ||

| Repetition accuracy | +/- 0.1 mm | ||

| Payload | 20 kg | ||

| Electrics | Design according to EN 60 204-1 | ||

| Base frame painting | 2C textured paint RAL 7035 (light gray) / RAL 3020 (red) | ||

| Input voltage |

3 x 400 V, 50 Hz or 60 Hz or country-specific adaptation |

||

| Rated power | approx. 2 kVA | ||

| Average consumption | approx. 1 kVA | ||

VariantS

- 1,000 x 1,000 x 300 mm (x/y/z)

- 1,500 x 1,000 x 300 mm (x/y/z)

- 2,000 x 1,000 x 300 mm (x/y/z)

- 2,500 x 1,000 x 300 mm (x/y/z)

- 3,000 x 1,000 x 300 mm (x/y/z)

- Optional Y-Axis 1,250 mm

- Optional Z-Axis 500 mm

- Further technical data or special sizes on request