Sealing of door modules

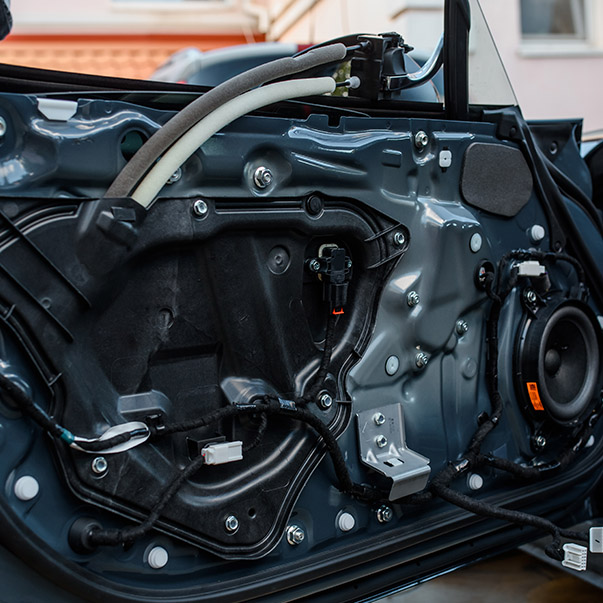

The car door has undergone a long period of development: from the simple foil seal of a bodyshell door and the integration of a few mechanical components, to the idea of a multi-unit carrier developed by leading OEMs. The so-called AGT door module is manufactured as a galvanized stamped sheet or, increasingly, from fiberglass-reinforced plastic, with recesses for the incorporation of electronic and mechanical units.

The car door is no longer just the barrier that represents a dry seal which protects the interior of the car from the wet exterior. On the contrary, the door module incorporates various forms of technology and electronics from the fields of safety, infotainment, lighting and air-conditioning. Drivers and passengers no longer would like to do without these features.

The contours of the AGT door modules and the units mounted on them, such as electric window controls, loudspeakers, door locks, etc., are sealed by our polyurethane foam gaskets and therefore protected against water and dust from the outside.

The seamless foam gasket of the AGT module is the water barrier between the wet and dry sides of the door shell. Furthermore, the foam gasket dampens noises and vibrations that occur when the vehicle is being driven.

The leading automotive suppliers have placed their trust for years in our Formed-In-Place Foam Gasket (FIPFG) dosing technology and wide selection of innovative material systems for sealing car door modules.

Are you also not satisfied until you have found the optimal and most flexible solution for your production? We are not satisfied until you are. This is the reason why our machine solutions focus on a dosing system which is very flexible and can be integrated into existing production concepts based on its modular construction.

Do you ask yourself how you can make your production processes more efficient with large quantities and short cycle times? We offer very reliable plant engineering with minimized maintenance intervals for your technical and commercial challenges.

As a result, you are provided with stable dosing processes for sealing foams with a high degree of precision and output efficiency, low material consumption and consistently high dosing quality from us as process experts in the field of FIPFG technology.

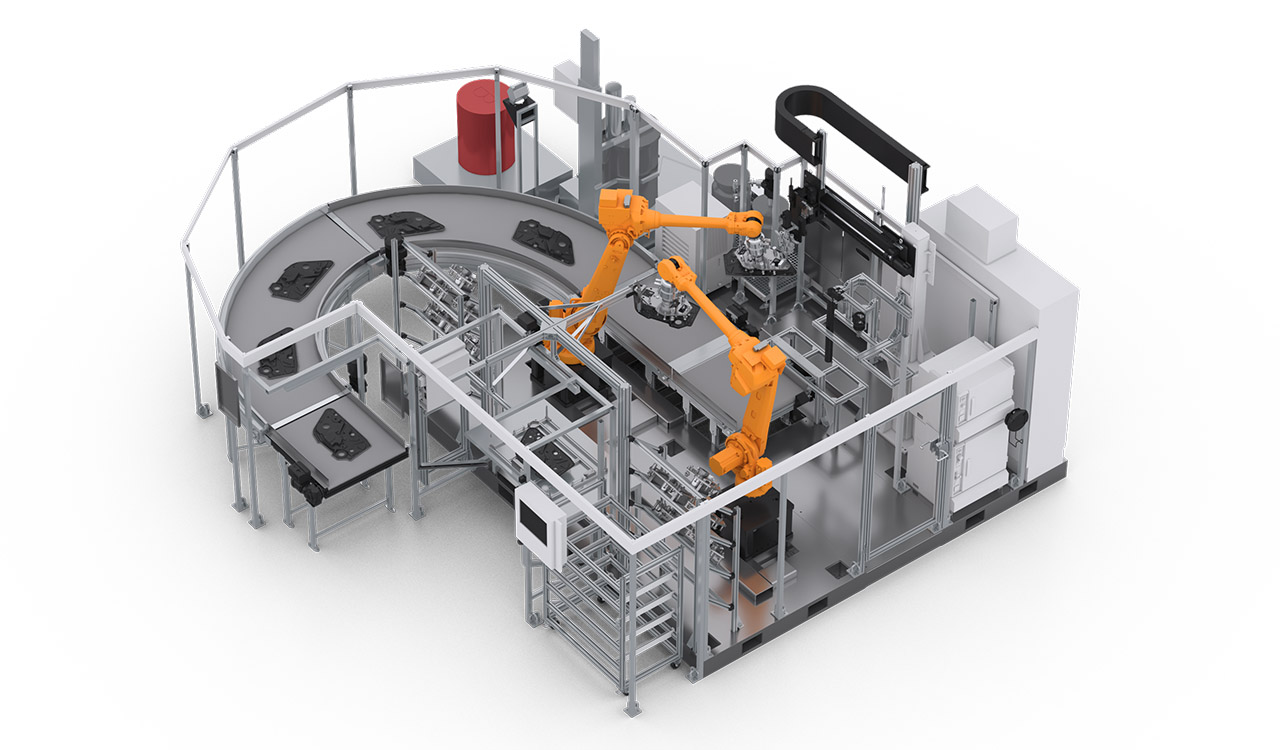

Animation of Sonderhoff DM 502 mixing and dosing machine for automated foam gasketing with 6-axis-robot for parts feeding and conveyor belt.

Customized sealing foams for seamless sealing of door modules

We develop customized solutions for your specific requirements

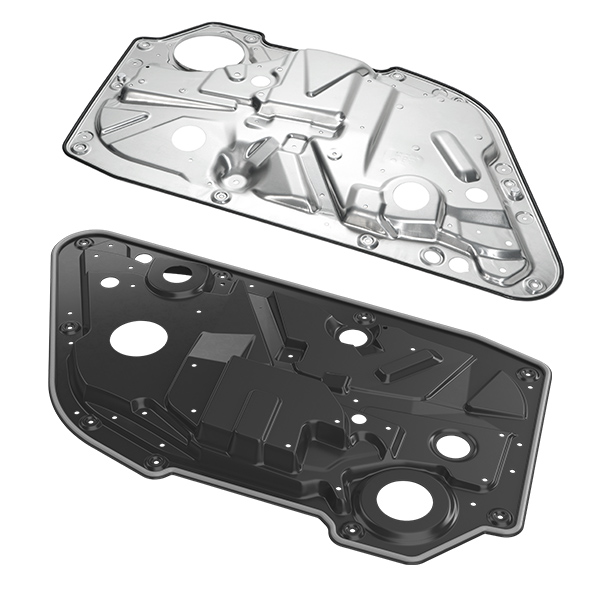

The unit carriers of car doors are predominantly made of galvanized steel, aluminum or, increasingly, fiberglass-reinforced plastic. Medium- to high-viscosity polyurethane sealing foams are used to seal the door module contours on a flat application surface or in a shallow groove. The dosing application is carried out fully automatically and very accurately with respect to the contours by means of the FIPFG technology of our mixing and dosing system.

The foam gasket on the entire module contour forms a seamless seal with a barely visible coupling point. Our polyurethane foams provide good adhesion on galvanized surfaces of carrier metal sheets. Adhesion to fiberglass-reinforced plastic often requires pretreatment with plasma. Due to the high level of impermeability offered by the foam gasket of the door module, which is compressed during installation, the car interior is separated from the weather outside. The electrical components on the door carrier are protected against water spray and dust. The seal also protects against rattling caused by the vibrations generated during driving.

The variably adjustable elasticity of the foam offers advantages with regard to low installation forces, during the assembly of the AGT door module and the mounting of electromechanical units on it.

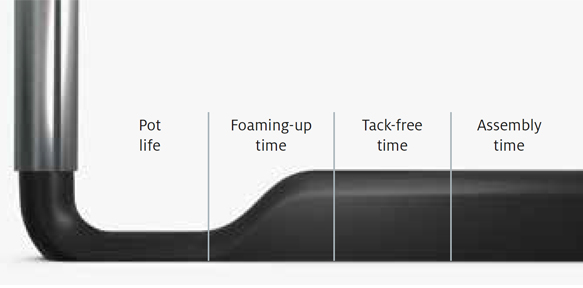

The different reaction phases of the sealing foam in the chronological sequence

Reference material

| Door module with groove | Door module without groove | |||

| FERMAPOR K31-A-5055-1-B | FERMAPOR K31-A-9199-29-VP3 | |||

| FERMAPOR K31-B-4 | FERMAPOR K31-B-81 | |||

|

Mixing ratio |

4.3 : 1 | 3.4 : 1 | ||

|

Pot life time |

65 sec. | 26 sec. | ||

|

Tack-free time |

3.5 min. | 7 min. | ||

|

Viscosity of the A component |

68,000 mPas | 52,000 mPas | ||

|

Density |

0.20 g/cm³ | 0.18 g/cm³ | ||

|

Hardness (Shore 00) |

48 | 30 | ||

|

Temperature resistance |

from -40 to + 80 °C | from -40 to +180 °C | ||

|

Pretreatment |

Plasma for e.g. PP and PE | Plasma for e.g. PP and PE |

In addition to the reference products, we develop material systems according to your individual requirements. Influencing factors include pot life until start of foaming, curing time, and the viscosity, hardness and adhesion properties.

Repeated removal and reinstallation of the door module or the components mounted on it, while maintaining a consistent sealing effect

The very good resetting ability provided by the foam gasket allows the repeated removal and reinstallation of the door module or the components mounted on it for repair purposes in the event of damage, without any reduction in the degree of tightness.

The use of fast-reacting and curing 2-component sealing foams enables short application processes and the rapid processing of parts in your production until the final acceptance of the AGT door modules.

The unpressed polyurethane foam gasket before installation.

Pressing the foam gasket achieves the required degree of tightness in the installed condition.

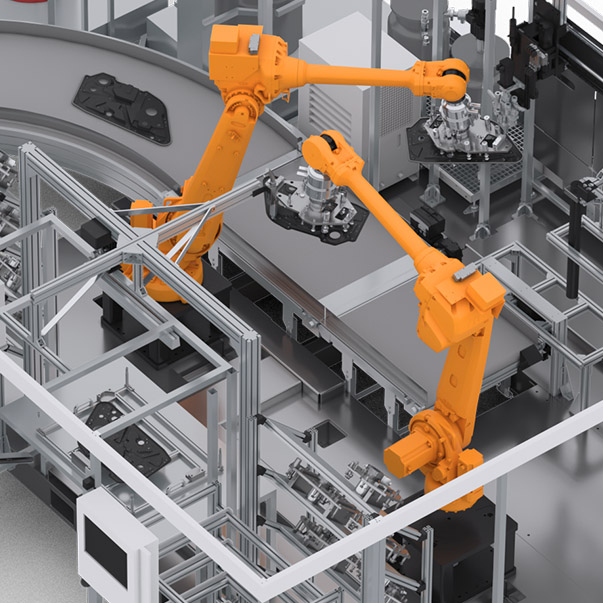

Mixing and dosing system with two 6-axis robots and plasma station, as well as a conveyor belt for the efficient feeding of the materials

Flexible and fully automatic – fully in line with your requirements

We support you with our application engineering expertise from the design phase of your AGT door modules to fully automated material application using Formed-In-Place Foam Gasket (FIPFG) technology. With the usually high volumes of parts and process speeds, an important success factor for the efficiency of our overall solution is the optimal integration into your manufacturing processes. As process experts, we work together with you to develop your individual automation solution according to your requirements.

To achieve this, we offer various configuration and equipment options for semi-automatic or fully automatic production systems.

In the illustrated reference configuration of the DM 502 mixing and dosing system, two 6-axis robots are used. These take over the handling of the parts in alternating cycles, from the transfer to the plasma station and then to the dosing station, until they are placed on the outfeed conveyor. At the start of the process, robot 1 takes over the door module from the parts holder of the transfer station, before positioning and moving it under the plasma nozzle. Here – in order to improve the strength of adhesion of the foam gasket – the surface of the door module contour is activated with atmospheric pressure plasma.

The robot arm then moves the door module under the mixing head, mounted on the traversing unit, for contour-accurate dosing of the sealing foam. In this process, the material is applied with a high degree of dosing and repeat accuracy into the shallow groove or onto the flat door module contour. The coupling point of the foam gasket closes seamlessly and is almost invisible.

At the same time, robot 2 picks up the next door module from the transfer station. In the closely timed production cycle, robot 1 has already placed its part on the transfer belt for clocking out and starts the new process with the next part.

The material components of the polyurethane foam used are mixed dynamically and homogeneously in the mixing head of the DM 502. The resulting fine-cell foam structure is crucial for low water absorption. When installed, the uniform compression of the seamless foam gasket produces a consistently high level of tightness over the entire contour of the AGT door module.

Material pressure tanks

Mixing head 825 PRO

2-axis mixing head traversing unit

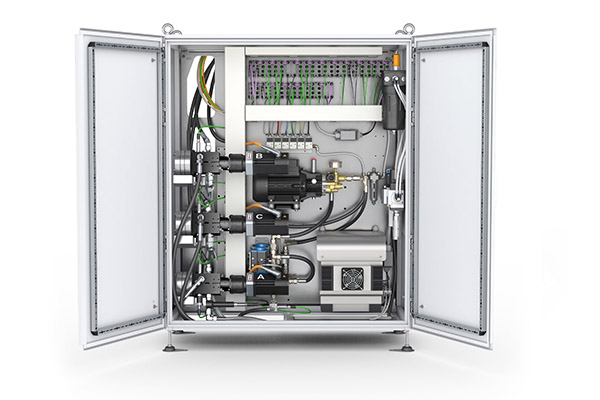

Dosing machine cabinet

Control cabinet

MP 2 mobile panel

CONTROL 2

Elevator

Supply Tap

Material pressure tanks

Mixing head 825 PRO

2-axis mixing head traversing unit

Dosing machine cabinet

Control cabinet

MP 2 mobile panel

CONTROL 2

Elevator

Supply Tap

Material pressure tanks

Material pressure tanks (24 l or 44 l, single-walled or double-walled) with minimum level sensors, on a grating platform with adjustable leveling feet

More information to our material Pressure TanksMixing head 825 PRO

MK 800 PRO precision mixing head with high-pressure water rinsing or alternative component rinsing system

More information to our mixing heads2-axis mixing head traversing unit

For the precise positioning of mixing heads to different positions for the application of polymeric reactive materials – optionally with electric or pneumatic drive.

More information to our traversing unitDosing machine cabinet

The dosing machine cabinet contains the components of the dosing periphery, e.g. the dosing pumps.

More information to our dosing machine cabinetsControl cabinet

The control electronics, safety engineering and industrial PC are installed in the control cabinet.

More information to our control cabinetsMP 2 mobile panel

The multifunctional MP 2 mobile panel (10.1” WXGA TFT) enables convenient operation of the dosing system.

More information to our operating panelsCONTROL 2

Optionally available: CONTROL touchscreen operating panel (21.5“) for operating the dosing system

More information to our operating panelsElevator

"Optional: Automatic ELEVATOR drum refilling station for the A-component with pneumatic lift and agitator"

More information to our refilling stationsSupply Tap

Optional: Automatic SUPPLY TAP drum refilling station for low-viscosity products, e.g. isocyanate (B-component)

More information to our refilling stations